SVCW General Manager Dan Child kicks-off a workshop meeting in Menlo Park about the new SAF-MBR project.

Can 1+1=3, or maybe even more? That is the question Stanford and Silicon Valley Clean Water (SVCW) hope to answer with two pilot plants using an innovative anaerobic secondary treatment process.

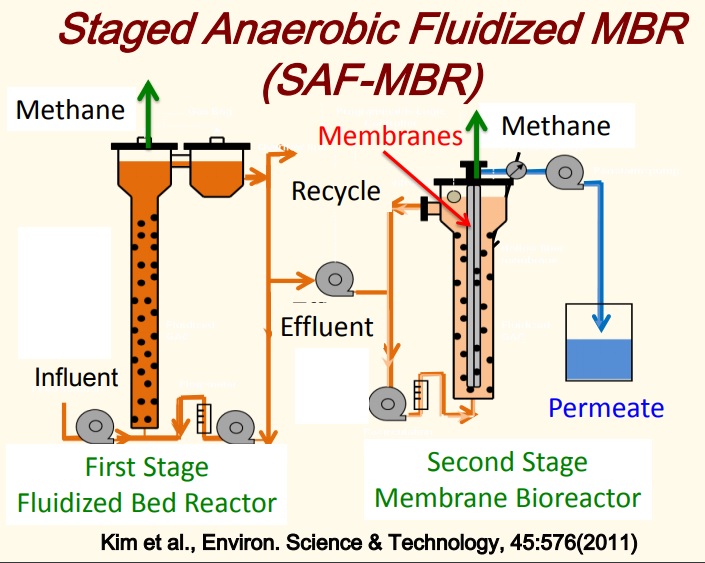

The ‘SAF-MBR’ project, which stands for Staged Anaerobic Fluidized-bed Membrane Bioreactor, has two main components – the membrane system and the fluidized-bed. Both are already used in wastewater treatment systems. The innovation is using them together in an anaerobic process for secondary treatment.

The four-year pilot study has an overall budget of $3.2 million, and is partially funded through a $2 million grant from the California Energy Commission, plus contributions from Stanford University, Silicon Valley Clean Water, Suez Water Technologies (formerly GE Water), Santa Clara Valley Water District, and LG NanoH20.

In October, SVCW launched the project at a kick-off meeting in Menlo Park where project leaders outlined the technology and reviewed results from the SAF=MBR’s operating at Stanford and in Korea.

Dr. Sebastien Tilmans will oversee construction of the new facility and is Director of Operations for William and Cloy Codiga Resource Recovery Center at Stanford, where the first pilot facility is currently operating.

“The fluidized bed and the membrane reactor are both tried and true,” he explained. “We’re just putting them together in new and unprecedented ways.”

SAF-MBR process

The first pilot, at Stanford, is capable of treating approximately 10,000 gallons per day of wastewater. The wastewater goes through primary treatment consisting of grit removal and a micro screen.

The process is anaerobic, eliminating the necessity for aerators, which is typically the largest user of energy in the wastewater treatment process.

Instead of relying on an aerobic process that would produce large amounts of biosolids during BOD removal, the anaerobic system converts most BOD to methane, producing 30-50% less biosolids than a conventional treatment system.

It’s estimated methane production will be double the amount normally produced at a conventional plant with digesters and aerobic secondary treatment.

“We plan to demonstrate that reducing our footprint reduces our operations and maintenance costs,” said Eric Hansen, a Senior Civil Engineer at SVCW and the project manager. “The nice thing about anaerobic processes is there are fewer systems with fewer moving parts, which is always the goal when designing robust systems. Simple systems are easier to operate and maintain.”

SAF-MBR inventor and Stanford Professor Perry McCarty at the Menlo Park kick-off meeting.

In addition to the power savings and increased methane production, the previous pilot system in South Korea demonstrated that the SAF-MBR may be better at removing Constituents of Emerging Concern (CEC), such as pharmaceuticals, which leads to an important benefit for water reuse.

As part of the pilot project SVCW has the ability to add pilot-scale skids for further treatment of the SAF-MBR’s effluent, including separate skids for Reverse Osmosis and UV-oxidation for potable water production, and a chlorination skid for non-potable water.

SVCW’s pilot facility is double the capacity of the Stanford plant at 20,000 gallons per day. Construction will begin in 2018. Demonstrating the technology at a municipal treatment plant is an important step in the pilot process. The second pilot will include important design improvements and will take the lessons learned from the Stanford pilot plant and apply them to a municipal treatment plant.

Future use of a full scale SAF-MBR process at SVCW could reduce the treatment footprint from three processes to one, replacing their secondary or activated sludge system, clarifiers, and dual media filters. Any decommissioned tanks or clarifiers can be re-used for water recovery.

Future aspects of the pilot process include discussions with the regulatory community to determine the viability of using the SAF-MBR process for non-potable and potable reuse.

“Exploiting the benefits of anaerobic treatment is a fundamental shift from conventional water recovery that has been based on oxidation. This shift will need to be proven before we can use it for non-potable and potable uses, something we plan to do with this demonstration,” said Eric.

Sebastien will also be involved in the pilot plant at SVCW. “This process has important potential benefits for water reuse,” he said.

What is SVCW’s overall goal for the pilot project? Eric explained:

“We hope to show we can increase the effectiveness of treatment at a lower cost so water recovery becomes cheaper and more reliable than imported water. The better we clean the water, the more resilient our water recovery system becomes for both non-potable and potable uses.”

“This is definitely a revolution in the industry,” he concluded.