From LIFT’s featured facilities page…

What technologies are you interested in investigating?

Silicon Valley Clean Water (SVCW) has been investigating all aspects of wastewater resource recovery for a while now. Currently SVCW is investigating SAF-MBR for low cost wastewater treatment and water recycling, collaborations with innovators to produce low energy solids drying and beneficial biosolids production including biodegradable plastics, food waste to energy digestion, and battery storage in support of renewable off-grid power supplies.

What are your facility drivers/needs?

What are your facility drivers/needs?

Silicon Valley Clean Water strives to provide the most cost-effective resource recovery facility possible. As with many regions, we face water scarcity, high energy costs, and high traffic congestion. Our agency sees itself as a resource recovery facility and we are looking for ways we can provide regionally self-reliant water supplies through integrated water management, reduce the production of high liquid biosolid waste that will reduce traffic from solids handling trucks to landfills, as well as maximizing the production of low-cost energy by leveraging available anaerobic treatment and digester biology.

How has LIFT helped, or how would you like LIFT to help your facility?

As with any research project, we all can benefit from the deep technical knowledge and experience available in our field. LIFT provides a great platform to facilitate this information exchange. We are always looking for ways we can improve the way we do business and we are looking forward to benefiting from the insights and ideas shared through the LIFT network, as well as share our knowledge and experience to benefit all of us and future generations.

If there were one technology you would pilot or collaborate on tomorrow, what would it be?

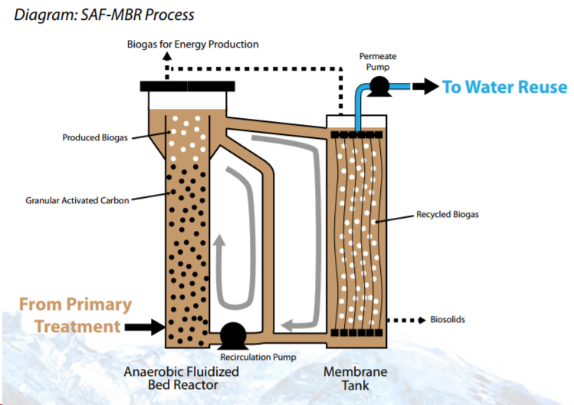

SAF-MBR (Staged Anaerobic Fluidized bed-Membrane Bioreactor). SAF-MBR uses anaerobic microbes to help purify water instead of their aerobic cousins that currently require a remarkable 3% of the nation’s electricity demand to treat water. Some benefits of the process are: biosolids are reduced by 30% or more, thus reducing energy, truck traffic, and GHG emissions; a smaller treatment train footprint offers more efficient use of facilities, resulting in operations and maintenance benefits.

In partnership with Stanford University, SVCW applied for a grant from the California Energy Commission (CEC), received the highest ranking of all applicants, and was awarded the $2 million maximum grant amount.

In addition to SVCW’s cash contribution of up to $500,000, other cash contributions from Stanford, as well as in-kind technology/equipment and engineering contributions from SUEZ Water Technologies & Solutions, Trojan Technologies, Santa Clara Valley Water District, and LG NanoH2O were received.

Cash and in-kind contributions total about $3.2 million, leveraging SVCW’s cash contribution to better than a 6:1 ratio. This SAF-MBR demonstration project (the largest of its kind in the world) will be built at the SVCW plant as a “closed-cycle,” utilizing primary effluent and influent which will then go back into the regular treatment process.

Once proven at this scale, operational and maintenance knowledge gained from this demonstration project will be used to understand the feasibility of further process scaling to meet the needs of SVCW and open the door to this new technology for other water treatment facilities throughout the world.

For more information, contact:

Eric Hansen

Senior Civil Engineer

Silicon Valley Clean Water

650.832.6228