How did a 12 MGD facility beat out huge treatment plants around the world for Project of the Year? By digesting food waste diverted from landfills and creating a carbon-negative operation.

It takes something pretty amazing to impress the water industry experts who nominate and vote in the Global Water Awards. This year’s wastewater project of the year nominees included huge facilities in China and Saudi Arabia. But a project by Victor Valley Wastewater Reclamation Authority (VVWRA)—a 12 MGD facility serving a few hundred thousand people in the high desert of California—won out over the big players this year, earning admiration for “demonstrating how technically advanced retrofits of old digesters can make the utility a net energy exporter at the same time as reducing its carbon footprint.”

In fact, VVWRA reduced its carbon footprint to less than nothing. It now prevents more greenhouse gas emissions than its operations create. It does this by co-digesting food waste that’s been diverted from landfills, eliminating the methane emissions that this waste would have caused in the dump. The facility converts 235,000 tons per of year of organic waste—in the form of food slurry and biosolids—into 320,000 MMBTU/year of carbon-negative biomethane, reducing greenhouse gas emissions by more than 72,000 tons per year.

And, while it’s doing good for the planet, it’s also doing good for its ratepayers, by creating new income streams that help to stabilize rates and fund new capital improvement projects without impacting service costs. The revenue comes from tipping fees for accepting organic waste and a share of the sales of the renewable natural gas it puts on the grid. What’s more, VVWRA completed the project via a public-private partnership (P3), eliminating upfront investment and risk to ratepayers.

In 2016 California passed a mandate (SB1383) to divert food waste from landfills, and VVWRA saw an opportunity. The utility could build on its existing digestion capacity and create a state-of-the-art facility to co-digest high-strength food waste along with its wastewater biosolids.

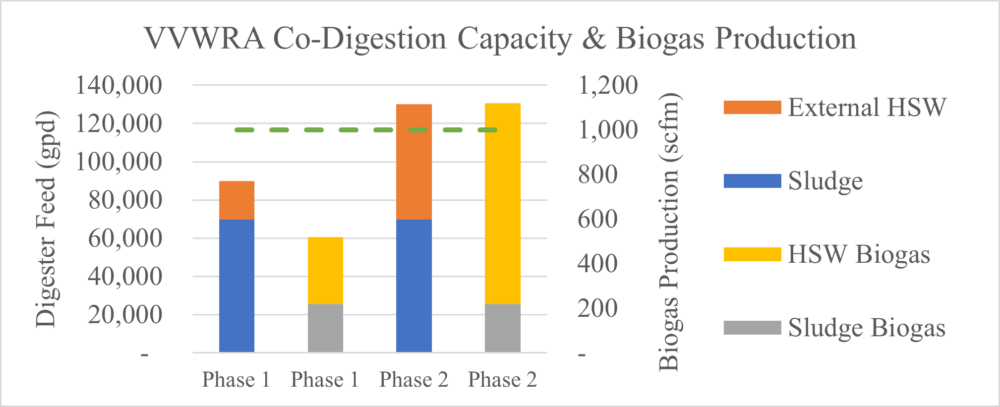

“By retrofitting with Anaergia’s high-solids digestion technology, we saw we could vastly expand our anaerobic digestion capacity,” said VVWRA’s General Manager Darron Poulson. “This robust technology allowed us to triple the capacity of our existing digesters with absolutely zero expansion of the footprint of our digesters.” The additional capacity would provide alternative organics disposal capacity to meet California’s growing need to digest food scraps, while allowing VVWRA to upgrade its public infrastructure.

VVWRA received strong interest from waste haulers seeking competitive tip fees, local food waste slurry disposal options, and the regulatory compliance offered by VVWRA. In fact, available feedstock exceeded the receiving capacity of VVWRA.

VVWRA had previously added combined heat and power (CHP) generation that was creating power for the facility. As VVWRA looked to increase organics processing capacity, Anaergia worked with the agency to conduct a cost-benefit analysis to find out which use of the added biogas would be the most economically favorable.

“We needed to find out which would make more economic sense,” says Anaergia’s Project Manager Margaret Laub. “Should they use the expanded biogas production to increase power generation? Or would the analysis favor upgrading the added biogas to renewable natural gas?”

The assessment indicated that the value of RNG sales—driven by renewable energy credits that monetize the fuel’s low carbon-intensity and potential to offset fossil fuel use—far exceeded the value generated from using biogas for CHP. Further, the potential RNG value would more than offset the cost of natural gas purchases to continue operating VVWRA’s CHPs for resilient onsite energy production.

“Upgrading 100% of the biogas from the plant’s digesters to pipeline-quality RNG is so favorable economically that the P3 entity can actually cover the cost of the fossil natural gas to run the CHP,” says Laub. “So VVWRA benefits from continued energy independence and resilience and avoids stranding its CHP asset, without having to pay for the fuel.”

The findings at VVWRA are generally consistent with the analysis of similar wastewater biogas projects throughout California and North America. When sufficient biogas production scale is achieved, then upgrading and conditioning this biogas to pipeline-quality RNG will create the greatest value, even where CHP systems are already in place. And this approach creates additional meaningful benefits by generating carbon-negative RNG, a cost-effective tool in achieving carbon-neutrality goals and mitigating climate change.

Based on the results of the analysis, VVWRA partnered with Anaergia, which formed a special purpose vehicle (SPV) called SoCal Biomethane LLC, to develop, design, build, finance and operate a state-of-the-art co-digestion and biogas upgrading facility. The project included facility upgrades to expand co-digestion including:

Three mothballed digesters were brought back online, increasing active digestion capacity by 50%. The facility is now using 990,000 gallons of previously unused digester capacity and has the ability to receive 100,000 gallons of high-strength waste per day in the form of food scraps. Anaergia also provided ancillary upgrades such as dedicated digester feed lines to support overall operations for the plant and address capital improvement needs of the Authority.

Using a P3 to complete the infrastructure upgrades offered another benefit: rapid completion. The Anaergia subsidiary began construction of the RNG infrastructure in 2020 and completed it in just 15 months. The project was officially commissioned and injecting RNG to the Southwest Gas pipeline in early 2022.

A P3 structure solves two problems for small and mid-sized utilities like VVWRA. First, it provides the capital, avoiding up-front ratepayer investment as well as long-term RNG value risk. Second, small and mid-sized facilities with limited staff can tap into the “knowledge capital” provided by experts at a company like Anaergia.

The P3 structure for the VVWRA project works like this: Anaergia’s SoCal Biomethane subsidiary owns and operates the biogas utilization facility, located on a small parcel it leases from VVWRA. The Anaergia facility then receives all biogas produced at VVWRA and conditions it to remove contaminants such as hydrogen sulfide, volatile organic compounds (VOCs), and siloxanes. The conditioned biogas is upgraded via Anaergia’s Biogas Upgrader System (BUG™) to produce pipeline-quality RNG. The carbon-negative RNG is 99% methane and delivered to the Southwest Gas utility’s point of receipt for pipeline injection and sale, offsetting the use of fossil fuels.

Anaergia’s subsidiary also manages interconnection and offtake agreements for the sale of the RNG, as well as registration with renewable fuel standard programs to maximize renewable energy credits and RNG value. Anaergia recently announced that the RNG produced by the facility will be used to produce carbon-negative hydrogen and electricity for Toyota Motor North America’s logistics operation at the Port of Long Beach in California which handles import/exports for North America and processes about 200,000 vehicles per year.

VVWRA continues to own and operate all of the co-digestion equipment and ancillary upgrades. The utility also maintains responsibility for coordinating organic feedstock and receives hauler tip fees (approximately $13.20/m3, or $0.05/gal). These high-strength waste tips fees add up to $4,000/day (nearly $1.25 million per year).

In addition, VVWRA continues to benefit from energy resilience and electric grid independence via natural gas-fueled CHP.

This innovative project demonstrates that advanced high-solids anaerobic digestion—a technology platform originally created for the European agricultural sector—can be adopted by the wastewater sector to maximize the use of existing digester infrastructure, allowing co-digestion of food waste with biosolids to create renewable natural gas and reduce methane emissions that occur when food waste is landfilled.

Industry experts have noted that the VVWRA model can be easily replicated in thousands of wastewater treatment plants across the country and would have significant environmental benefits. While using anaerobic digestion to convert wastewater biosolids into pipeline-quality renewable natural gas is not new in the U.S., before VVWRA it had been practiced only at large WWTPs. Because 95% of plants in the U.S. are sized at less than 15 MGD, a large segment of the sector is currently missing out on the energy savings, GHG reduction, cost reductions, and new revenue stream potential that co-digestion offers.

Emulating a resource recovery project such as VVWRA’s throughout the U.S. water sector would improve wastewater infrastructure, provide clean energy, and improve air quality while reducing greenhouse gas emissions and addressing climate change. VVWRA’s innovative approach demonstrates that co-digestion upgrades at any size treatment facility can generate revenue, provide redundant capacity, enhance a utility’s energy independence–all while eliminating the operation’s carbon footprint.

“This project is really a cutting-edge example of how to effectively manage waste as a valuable resource, with the added benefit of doing good for the environment,” says Darren Poulson, VVWRA’s General Manager. “It not only gives us energy resilience, independence from the power grid, and increased capacity to serve our community, it also gives us a source of revenue.”

The Problem of Landfill Methane Emissions

When food waste and wastewater biosolids are landfilled, they contribute significantly to methane emissions. And landfills represent a much larger portion of methane emissions than is typically understood. If all of the methane from organic wastes were eliminated by diverting that waste from landfills, it would have the effect of eliminating more than 695 million tons of CO2e/year (based on a 20-year time horizon), which is more than 13% of total annual U.S. greenhouse gas emissions.

Rather than contribute to this issue through the generation of biosolids, wastewater plants can be part of the solution by leveraging existing digestion infrastructure. The VVWRA project demonstrates the critical role wastewater treatment plants of all sizes can play to combat climate change by preventing greenhouse gas emissions from organic waste and fossil fuel consumption, while improving infrastructure, increasing resilience, and creating alternative revenue streams.

Analysis showed it would be more economical for VVWRA to fuel its CHP with utility natural gas in lieu of biogas and upgrade 100% of its biogas to renewable natural gas.

VVWRA establishes a landmark reference for biomethane production at any such wastewater resource recovery facility (WRRF) in the U.S.