By Elise Chen1, Aleks Pisarenko1, Juan Guerreiro2

1 Trussell Technologies, Inc., Solana Beach, CA 92075

Email: [email protected], [email protected]

2 City of San Diego, Public Utilities Department, San Diego, CA 92123

Email: [email protected]

California is seeing a major expansion of water reuse applications throughout the state from non-potable recycled water to potable reuse. Non-potable recycled water involves treating wastewater to standards for agricultural uses, industrial uses, and landscape irrigation to off-set the use of potable water. For potable reuse applications, reclaimed water is first treated with advanced water treatment technologies, then discharged into an environmental buffer, where water is stored, before undergoing treatment at a drinking water facility. Advanced water treatment includes processes such as ozonation, biological activated filtration, membrane filtration, reverse osmosis, and ultraviolet/advanced oxidation process. California has developed regulations for discharge into two types of environmental buffers—groundwater and surface water. The degree of treatment required for groundwater and surface water augmentation differ, with surface water augmentation being the more stringent of the two. With regulations finalized, the next challenge is to provide the educational resources for developing professional operators with the skills and experience needed to operate and manage potable reuse facilities.

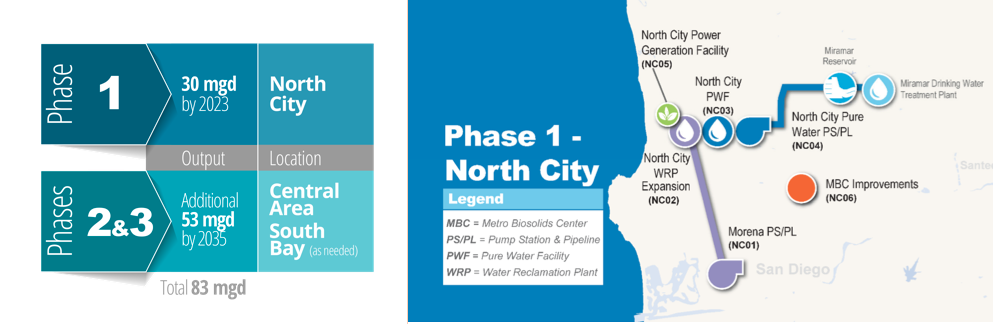

Potable water reuse as a practice is relatively young compared to water and wastewater and, as such, the labor pool is not large enough to match the upcoming demand. In 2015, the City of San Diego launched a massive potable reuse program called Pure Water San Diego which will provide one-third of San Diego’s Water supply locally by 2035. The first phase of this program will target production of 30 MGD of purified water starting in 2023 for surface water augmentation. With 2023 right around the corner, the City of San Diego has recognized the challenges of staffing a full-scale potable reuse facility with a limited labor pool of operators.

The City of San Diego has partnered with Trussell Technologies to design and execute a training program to prepare operators for operating a full-scale Full Advanced Treatment (FAT) train and for passing certification exams for advanced water treatment (AWT) operators once certification programs are available. The training program emphasizes building practical skill sets by providing hands-on experience opportunities and providing the educational resources to successfully apply theory of treatment to operations. Hands-on experience was cultivated at the 1 MGD Pure Water Demonstration Facility (PWDF) at the City of San Diego’s North City Water Reclamation Facility and education was provided to City drinking water and wastewater operators through intensive lecture-based classroom sessions.

Figure 1. Overview of San Diego’s Phase 1 of the Pure Water Program.

Figure 1. Overview of San Diego’s Phase 1 of the Pure Water Program.

In 2011, the Pure Water Demonstration Facility (PWDF) was constructed by the City of San Diego as a test facility for research and process optimization. This 1 MGD demonstration facility consisted of a FAT train with microfiltration (MF), ultrafiltration (UF), reverse osmosis (RO), and ultraviolet/advanced oxidation process (UV/AOP) at the North City Water Reclamation Facility. In 2014, the PWDF was expanded to include ozone and biological activated carbon (BAC) preceding the existing full advanced treatment train. The City of San Diego’s first full-scale potable reuse treatment facility, which will be called the North City Pure Water Facility, will utilize the same O3-BAC-UF-RO-UV/AOP treatment process currently used at the demonstration facility. In addition, the equipment and processes used at the demonstration facility are full-scale sized. Therefore, the demonstration facility became a perfect training ground for operators to learn new skills, master daily operations, and develop experience with troubleshooting and operating during challenging periods. Prior to training operators, Trussell Technologies played a key role in developing the design criteria for the North City Pure Water Facility. Once design criteria were set, the Trussell Technologies team developed and optimized an operations plan, maintenance plan, water quality monitoring plan, and standard operating procedures for the demonstration facility to document best practices to meet production, design, and regulatory requirements. These plans and procedures were executed first by Trussell Technologies at the demonstration facility to confirm that plans were feasible and practical for real-world application.

Figure 2. Pictures of the different treatment steps at 1MGD Pure Water Demonstration Facility.

Figure 2. Pictures of the different treatment steps at 1MGD Pure Water Demonstration Facility.

Once plans and procedures were vetted, hands-on training with operators started at the demonstration facility. In practice, new operators first shadow a trained operator and eventually start performing tasks independently with supervision as skills and knowledge were gained. The emphasis throughout hands-on training is to instill consistency of performance between different operators. The documented plans continue to be a great resource for promoting consistency since operators have access to the same information. The majority of daily tasks at a FAT facility revolve around collecting data to confirm that the treatment processes are operating as intended. The quality of collected data is critical since many operational issues may be detected before complete failure by studying data trends from each unit process. Once operators are comfortable with performing daily duties, operators are introduced to the expected ranges for each parameter that they record. Once ranges are memorized, operators are able to detect process excursions immediately and initiate corrective measures. This knowledge also allows operators to do their own quality control as they record data as part of their daily rounds. During these rotations, operators are exposed to troubleshooting and operating during challenging conditions that occur with feed water quality changes. Gaining these experiences is invaluable since many of these situations do not occur frequently and may be difficult to fully comprehend without having gone through the experience themselves. Once the rotation cycle is complete, operators feel comfortable in executing daily tasks and are ready to learn more about the theory of treatment and the context for why certain practices are emphasized.

There are many resources available on advanced water treatment processes and topics in the form of presentations, textbooks, etc. However, most resources are not tailored for operators, specifically. Trussell Technologies developed five course modules for ozone, BAC, MF/UF, RO, and UV/AOP. The goal of these modules was to capture information and topics most relevant for an operator to know. Each module covered the following topics: theory of treatment; system equipment and configurations; system monitoring, system controls; system maintenance; safety and hazards associated with systems; math as a tool for enhancing operations and confirming compliance; and the regulatory context for operational practices. Modules were delivered in an interactive classroom sessions where operators were engaged in solving operational case studies and problems using the knowledge gained in the classroom.

Figure 3. In class pictures of operator training.

Figure 3. In class pictures of operator training.

Training operators on new treatment processes and regulations is a daunting task at first due to the scope and depth of knowledge. While theoretical knowledge is important, operators must also be able to apply this knowledge in operations and develop the experience and skills to maintain stable operations. The City of San Diego continues to invest in their staff and provide them the opportunity and resources to gain both hands-on experience at a demonstration facility and classroom time to round out their training and education. With all the investment into operator training, operators will surely feel comfortable and prepared once the 30 MGD North City Pure Water Facility is started up in 2023.