By Brett Faulkner(1), Thomas Welche(2)

1 Trussell Technologies, Inc., 380 Stevens Ave, Suite 212, Solana Beach, CA 92075; e–mail: [email protected]

2City of Santa Barbara, 520 East Yanonali, Santa Barbara, CA, 93103; e–mail: [email protected]

Introduction:

The City of Santa Barbara (City) owns and operates the El Estero Water Resource Center (EEWRC). EEWRC treats approximately 6 million gallons per day (MGD) of domestic wastewater with secondary effluent either receiving tertiary treatment to be recycled for non-potable reuse or discharging to the Pacific Ocean via ocean outfall. In recent years the City has completed two major upgrade projects at the EEWRC:

Trussell Technologies Inc. has been working with EEWRC staff since 2016 to help improve membrane filtration performance and maintain effective treatment and recycled water production through the construction of the secondary process upgrades. Fouling issues with the automatic strainers upstream of the MF were experienced shortly after the conversion of the secondary process to NDN. The troubleshooting steps, corrective actions, and conclusions are shared in this article.

Automatic Strainer Background:

Automatic strainers are wire-screen strainers that automatically flush and serve as a protective pretreatment to MF. Automatic strainers are required as pretreatment for the MF process because they remove dirt and debris that could cause physical or structural damage to the membranes. Feed water enters the automatic strainer through an inlet on the inside of a cylindrical screen and flows radially outward. Particulates and debris larger than the screen mesh size collect on the inner surface of the screen. Warranties from the various MF module manufacturers typically require a screen mesh size of 200 to 300 microns (μm). The automatic strainers perform a self-cleaning flush periodically based on either a timer or differential pressure. Once a self-cleaning flush is initiated, an exhaust valve opens, creating a high velocity suction force utilized by rotating nozzles that hydraulically vacuum accumulated particulates from the screen’s surface. The suction nozzles rotate along the screen surface in a helical path by a two-way reversing motorized drive transmission. Feed water continues to flow through the strainer during the self-cleaning flush, so the feed flow to the MF process is uninterrupted. Two automatic strainers are installed at EEWRC between the MF feed pumps and MF skids. The strainer screens had a pore size of 300 micron and self-cleaning flushes are initiated every 30 minutes or based on a differential pressure through the strainer of 7 psi, whichever occurs first.

Automatic Strainer Fouling at EEWRC:

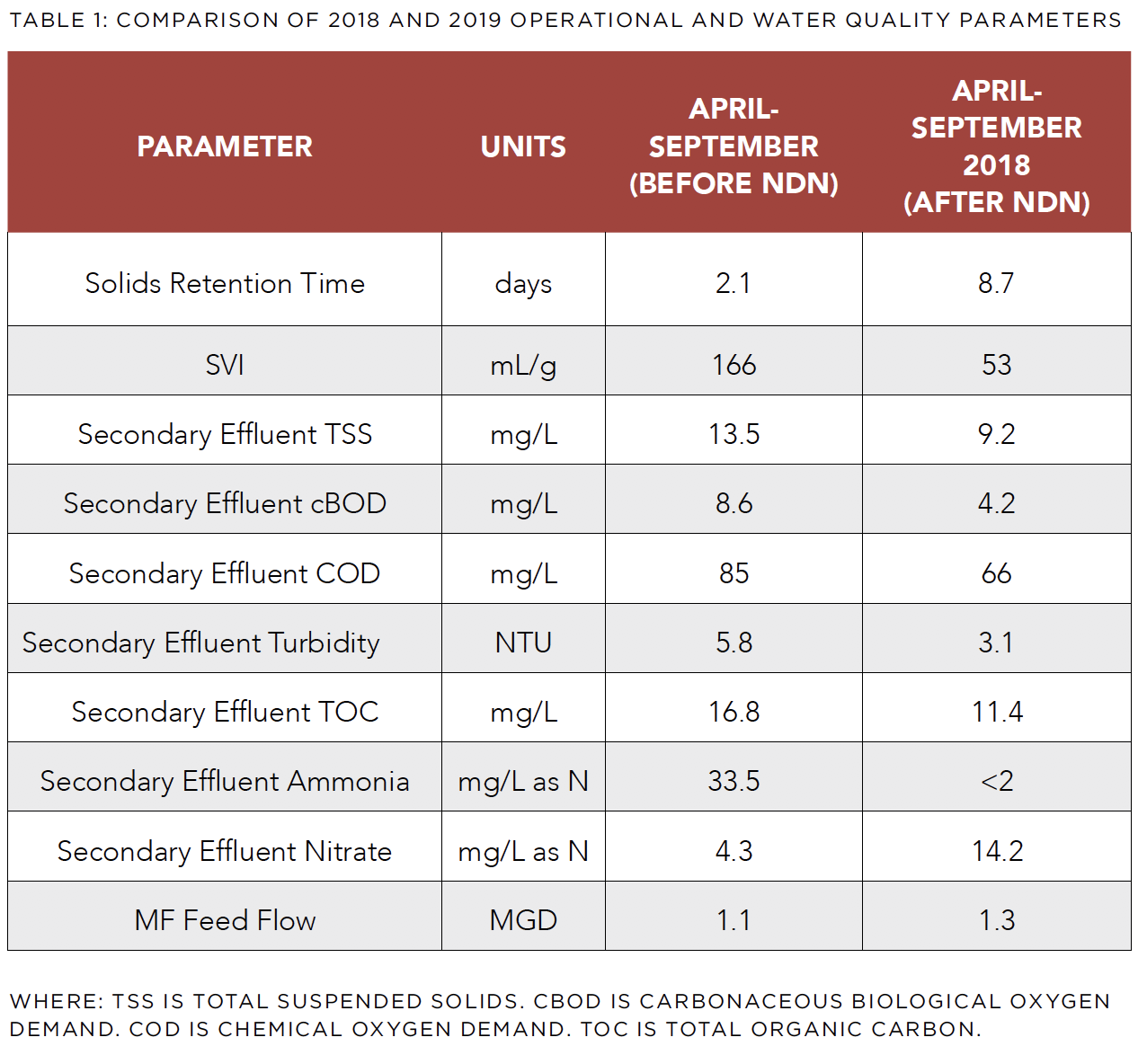

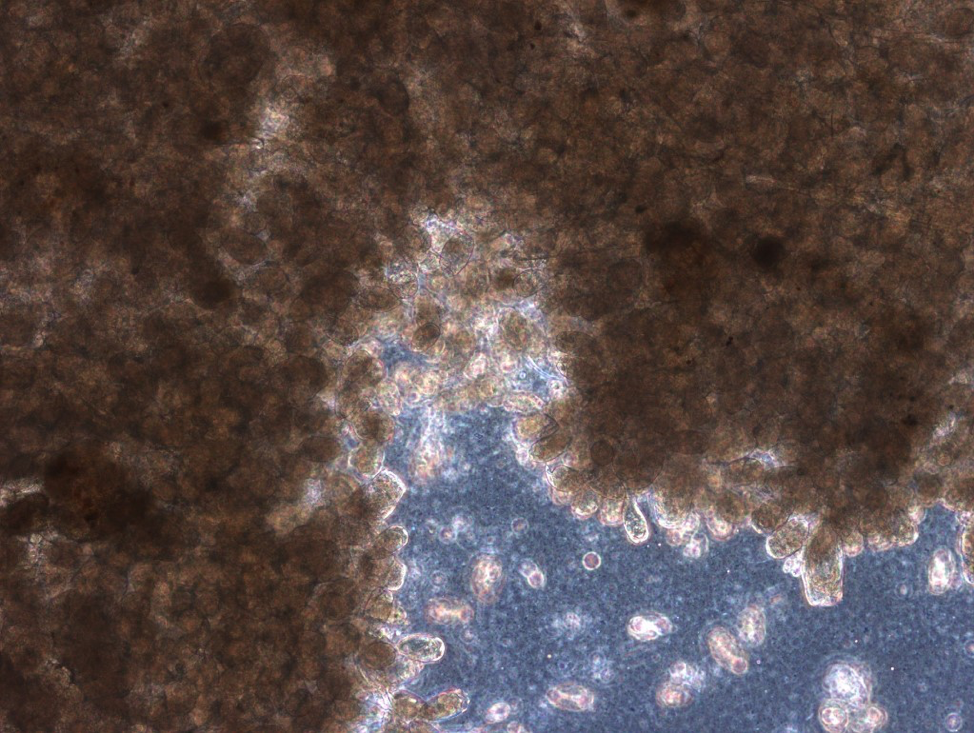

Between April 2016 and April 2019, the automatic strainers at EEWRC operated without major issues. The NDN conversion occurred in February 2019 and secondary effluent water quality improved considerably as a result. Table 1 summarizes secondary effluent water quality and several key process parameters before and after the conversion to NDN. The MF performance improved considerably (e.g., lower fouling rates, higher permeability) with the nitrified feed water, however the automatic strainers began experiencing issues shortly after the conversion to NDN. Differential pressure accumulated and the automatic flushes were ineffective, resulting in the automatic strainers flushing repeatedly. EEWRC staff had to shut down the MF system and physically remove the automatic strainer screens. This required the use of a crane to remove the strainer screen out of its housing as shown in Figure 1. Upon removal, light brown foulant was observed on the “clean” side of the strainer (i.e., outside of the strainer mesh), shown in Figure 2. EEWRC staff manually cleaned the screens with a power washer, reinstalled the screens, and restarted the MF system. The manual cleaning temporarily restored performance, however, the differential pressure accumulated over several days resulting in the same continuous initiation of automatic flushes. EEWRC staff repeated the manual pulling, cleaning, and replacing of the screens as needed with the same light brown foulant on the outside of the screens being observed each time.

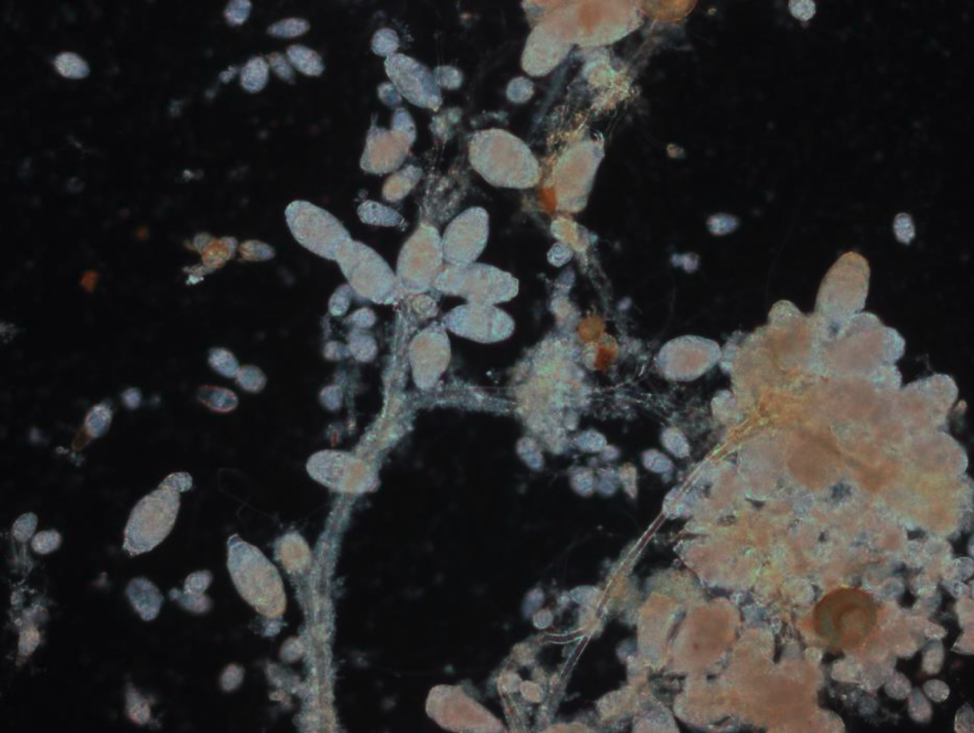

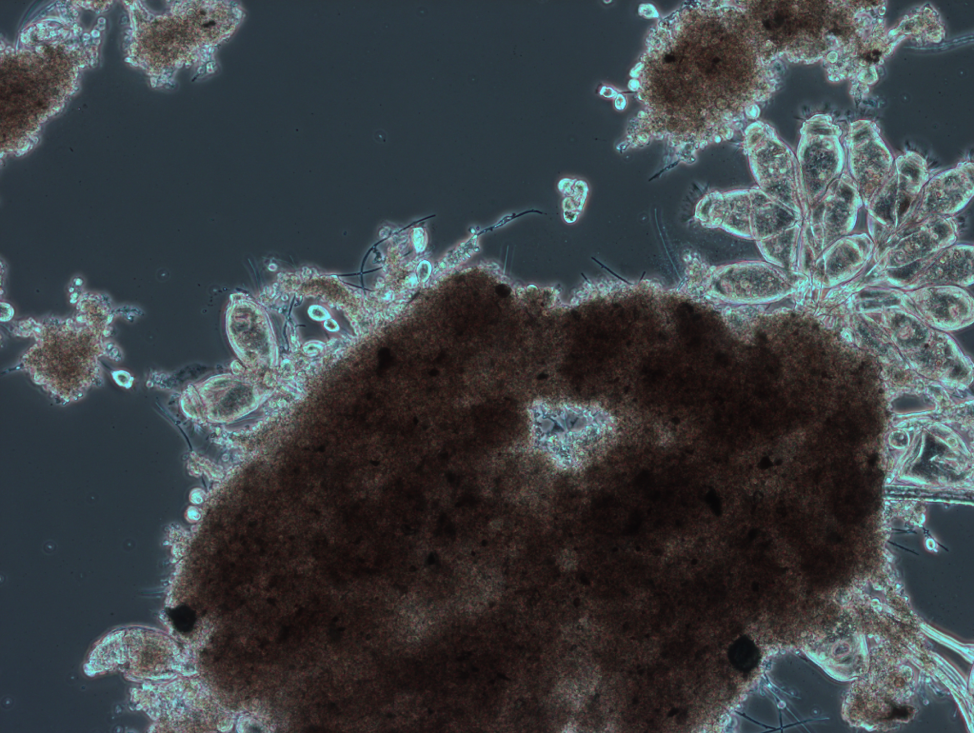

In late May 2019 a microscope analysis was performed on the strainer foulant to help identify the source or cause of the strainer fouling. The microscope analysis revealed that the foulant consists of an agglomeration of stalked ciliates, as shown in Figures 3 and 4. Stalked ciliates are protozoa that have an enlarged anterior portion or “head” and a slim posterior portion or stalk. The “head” has cilia around a mouth opening to capture and consume bacteria. These organisms typically attach to floc in activated sludge systems but can attach themselves to anything that can provide them a base. Stalked ciliates are commonly observed in mixed liquor and usually indicate a stable, healthy system with a mature activated sludge. Abundance of stalked ciliates usually indicate the biomass is forming well-structured floc that is essential to settling and good effluent quality. A picture taken from a microscope examination of the activated sludge mixed liquor at EEWRC is shown in Figure 5. As shown, the mixed liquor contains well-structured floc with colonies of stalked ciliates attached.

FIGURE 3: MICROSCOPIC EXAMINATION OF AUTOMATIC STRAINER FOULANT MATERIAL SHOWING AGGLOMERATION OF STALKED CILIATES.

FIGURE 4: PHASE CONTRAST MICROSCOPIC EXAMINATION OF AUTOMATIC STRAINER FOULANT MATERIAL SHOWING STALKED CILIATES.

The samples collected from the automatic strainers indicated that the stalked ciliates were inactive and dead. Sodium hypochlorite and ammonium sulfate are dosed upstream of the automatic strainers to maintain a chloramine residual through the MF system and control biofouling. The stalked ciliates are believed to originate from the upstream secondary process because: 1) the presence of chloramine residual through the automatic strainers inhibits biological growth, 2) microscope observation of the foulant revealed dead stalked ciliates, and 3) an abundance of alive stalked ciliates were observed in the mixed liquor.

Corrective Actions:

EEWRC staff continued to manually pull and clean the screens to maintain recycled water production. Since strainer fouling persisted, a technician from the automatic strainer manufacturer was brought in to inspect and perform diagnostics on the system. The technician concluded that the automatic strainers were operating and flushing properly.

Corrective actions were taken to mitigate the fouling at the automatic strainers rather than attempting to discourage or eliminate the stalked ciliates in the activated sludge since the biological process was performing well and the presence of stalked ciliates are an indicator of healthy biology. The following corrective actions were taken:

New screens with larger mesh size (500 µm) and spring-loaded nozzles were ordered in July 2019 with a lead time of 4 to 8 weeks. In the interim, a free chlorine residual was maintained through the automatic strainers to minimize the downtime and labor associated with manual cleaning. Free chlorine is a much more powerful oxidant than chloramines and the MF is tolerant to free chlorine exposure. It was theorized that free chlorine may break down the foulant so it either passes through the screen or is able to be more effectively removed by the flush cycles. Therefore, the ammonium sulfate was turned down and the chlorine dose was adjusted to maintain a free chlorine residual of 3 to 5 mg/L. The free chlorine did reduce the rate of fouling, extending the time between manual cleanings, but ultimately it did not resolve the issue. It warrants mention that free chlorine is not advised for MF systems that feed a reverse osmosis (RO) process as free chlorine will destroy RO membranes.

In late August 2019, the 300 µm screens were replaced with 500 µm screens and no fouling or accumulation of differential pressure through the automatic strainers has occurred since. The larger mesh size either allows the stalked ciliates to pass through the automatic strainers and/or improves the ability for the flushes to effectively remove them. The MF warranty does require 300 µm screens, however the MF modules at EEWRC are toward the end of the warranty period and the City’s emphasis is on reliably maintaining recycled water production and reducing operator burden. The 500 µm screens will still provide protection from debris, just to a lesser degree. As of writing this article, MF integrity has not been affected by the 500 µm mesh size screens.

The new spring-loaded suction nozzles were installed, and the free chlorine was converted back to chloramines in late September 2019. No effects were observed due to these changes and low differential pressure through the automatic strainers has been maintained. The City may swap out the 500 µm screens with the original 300 µm screens in the future to determine if the new nozzles are able to prevent automatic strainer fouling alone.

Summary and Conclusions

The following summarizes the EEWRC automatic strainer fouling experience:

FIGURE 5: MICROSCOPE EXAMINATION OF EEWRP MIXED LIQUOR WITH STALKED CILIATE COLONIES ATTACHED TO FLOC.

The purpose of this article is for the City to share their tribulations and resolution of repeated automatic strainer fouling after significantly improving the MF feed water quality. The experience at EEWRC suggests that the 300 µm screen mesh size required by many MF manufacturers have a potential risk of fouling with stalked ciliates that are common in activated sludge systems. This could be related to the morphology of stalked ciliates, but more research or experience is needed. Typical water quality metrics (e.g., TSS, BOD, turbidity) does not appear to be influenced by stalked ciliates as the feed water quality was substantially better during the automatic strainer fouling compared to prior operation. The solution that worked for the City may not be viable for other utilities due to MF manufacturer warranty requirements. The use of MF to treat secondary effluents is becoming much more prevalent for recycled water or potable reuse applications. As more utilities install MF systems, it will be interesting to see if similar automatic strainer fouling is experienced.