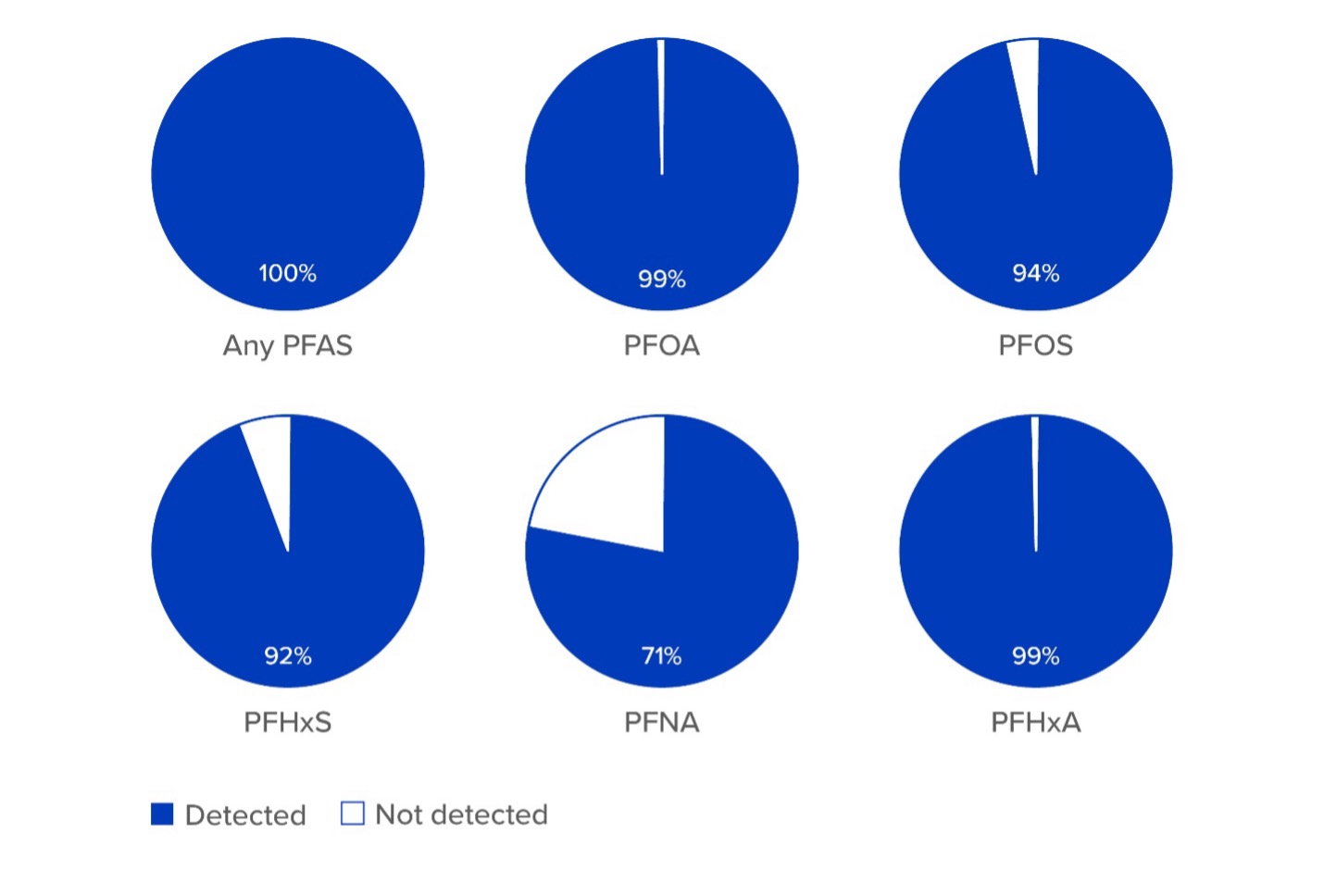

Per- and polyfluoroalkyl substances (PFAS) are pervasive contaminants detectable in all wastewater effluents, even in the absence of direct industrial sources. Water resource recovery facilities (WRRFs) act as passive receivers of these substances. While precursor PFAS compounds often transform into terminal forms detectable in effluent using methods like EPA Method 1633, WRRFs typically lack the processes to destroy PFAS altogether.

PFAS are detectable in all wastewater effluent. Source: Thompson, K. A. et al. 2022. ACS ES&T Water, 2(5), 690–700.

In 2022, the EPA released a memo outlining strategies to address PFAS discharges in National Pollutant Discharge Elimination System (NPDES) permits, emphasizing the importance of monitoring and source control. Key recommendations include:

The EPA has also started providing recommendations that will potentially impact WRRF effluent and solids management. In December 2024, the EPA released draft health-based recommendations for PFOA, PFOS, and PFBS in water bodies. In January 2025, the EPA released its long-awaited draft sewage sludge risk assessment for PFOA and PFOS. While both of these documents are recommendations and not enforceable, they reiterate the EPA’s dedication to limiting PFAS in wastewater discharges.

Controlling PFAS at the source is the most cost-effective strategy. However, even in the absence of industrial sources, residential sources contribute PFAS to WRRFs. This results in the challenge of treating higher flows of wastewater with more dilute contaminants. Established separation technologies like granular activated carbon (GAC), ion exchange (IX), and reverse osmosis (RO) are viable for water and reuse applications, but their feasibility for secondary effluent is doubtful without intermediary steps for further organic matter and particulate removal. Our sector’s experience with potable reuse gives insight into the high costs of installing similar processes for PFAS. 1

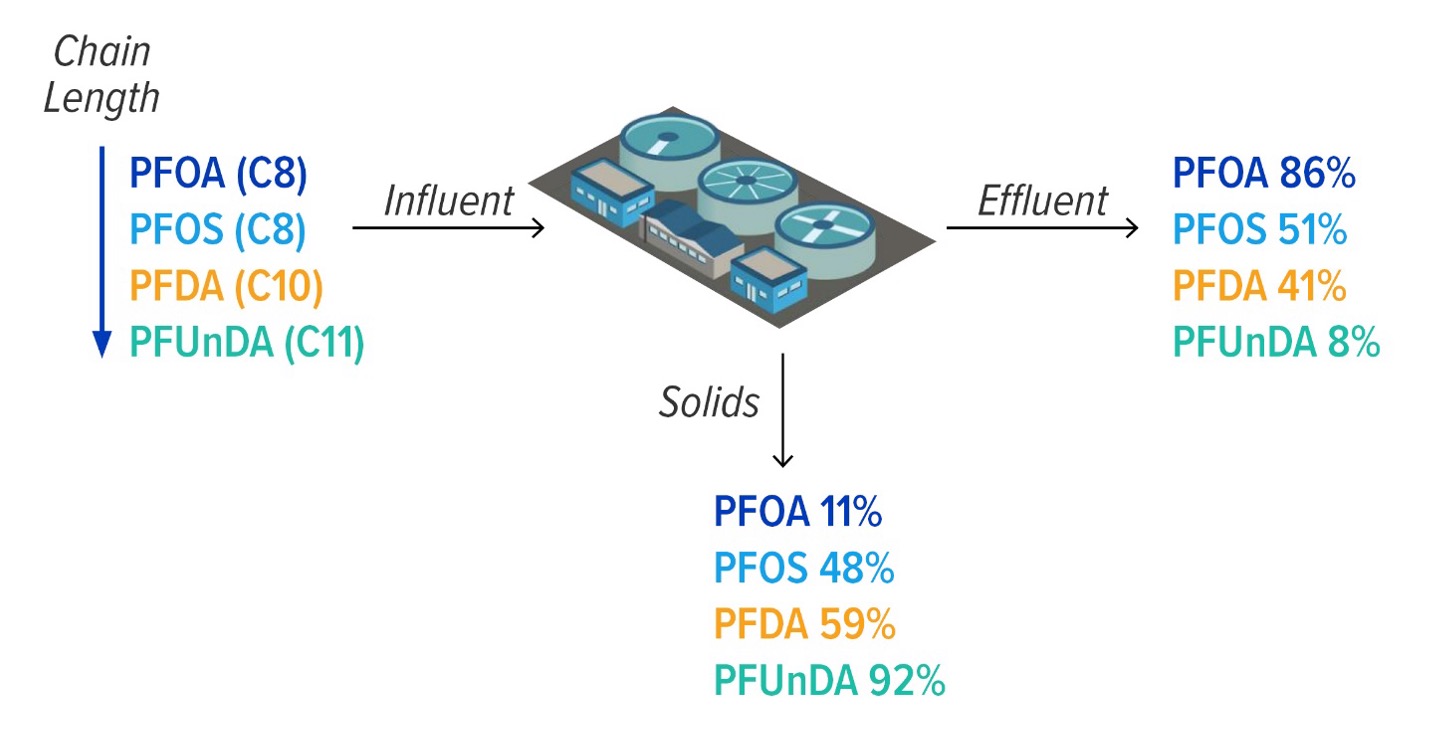

A significant portion of PFAS in wastewater influent ends up in the solids stream, particularly higher molecular weight, long-chain PFAS. Two such compounds, PFOA and PFOS, were the focus of a recent EPA draft risk assessment. The assessment modeled conservative scenarios in which land-applied biosolids could pose health risks to farm families relying heavily on on-site food and water. While not a regulation, the draft has raised concerns about future limitations on land application.

With over half of U.S. biosolids currently land-applied—and growing concern that state-level limitations or liability issues could impact this practice—utilities should proactively evaluate diversified management strategies. These could include landfilling (where permitted), incineration, drying technologies, and advanced thermal processing technologies with potential for PFAS destruction. While still emerging, advanced thermal processes show promise and merit further evaluation, particularly as the industry seeks scalable, long-term solutions.

Longer-chain PFAS mostly go to biosolids and shorter-chain PFAS mostly go to effluent. Adapted from: Arvaniti, O., et al. 2014. Chemosphere, 111, 405-411.

Given the regulatory uncertainty and complexity of PFAS management, the following recommendations can guide utility managers, engineers, and treatment plant operators:

Addressing the challenges of PFAS in wastewater requires a multifaceted approach, combining monitoring, source control, strategic planning, and proactive communication. By staying informed and prepared, the water and wastewater industry can navigate the complexities of PFAS and protect public health and the environment.

1. 1 Sim, Alison, and Meagan S. Mauter. “Cost and energy intensity of US potable water reuse systems.” Environmental Science: Water Research & Technology 7, no. 4 (2021): 748-761.↩

About the Author

Dana Gonzalez is a principal technologist at Carollo Engineers, where she serves as the California PFAS lead and as a leader in wastewater innovation. Dana has led various projects focusing on nutrient removal, resource recovery, water reuse, solids handling, PFAS fate and transport, system and equipment optimization, process control design and tuning, and process modeling. She holds a bachelor’s degree from UCLA, a master’s degree from Virginia Tech, and a PhD from the University of Virginia.