Biological nutrient removal (BNR) is an essential secondary treatment process used in many Water Resource Recovery Facilities (WRRFs) to remove nitrogen (N) and phosphorus (P).

Traditional activated sludge processes are effective at transforming ammonia to nitrate but usually operate at high dissolved oxygen (DO) concentrations greater than 2 mg/L. While effective, plants operating at higher DOs use 45 to 60 percent of a plant’s energy demand for aeration.

“Low dissolved oxygen (0.2-1.0 mg/L) or suboxic biological nutrient removal (SBNR) (0.2-0.7 mg/L) have emerged as successful strategies for reducing energy consumption while simultaneously providing effective BNR,” said Phil Ackman, PE, LACSD Supervising Engineer of the Research Section. “SBNR shows potential to provide consistent nutrient removal performance by exerting selective pressure on microbial communities involved in nitrification, N removal, and biological P removal to adapt and perform effectively at low DO concentrations.”

While several plants across the U.S. have implemented low DO with varying levels of success, little has been communicated on what is required to design and operate an SBNR plant. As part of the Department of Energy project DE-EE0009509, Transforming Aeration Energy in Water Resource Recovery Facilities (WRRFs) through Suboxic Nitrogen Removal, Carollo Engineers led a team seeking to gain better insights into SBNR operations, including design, implementation, and operation of SBNR plants.

Pomona WRF: Retrofitting a Full-Scale Plant for Low DO Operations

The Sanitation Districts of Los Angeles County’s (LACSD) Pomona Water Reclamation Plant (WRP) provided an excellent opportunity to gain valuable information on low DO design and implementation. Pomona WRP is a 15 MGD modified Ludzack-Ettinger activated sludge plant (Figure 1). Primary clarification precedes three parallel activated sludge tanks used for nitrogen BNR (ammonia seasonal limits of 3.0 to 3.9 mg/L, total inorganic nitrogen less than 8 mg/L, and no P limits).

Each activated sludge train has one anoxic zone followed by two aeration zones. The plant serves as a scalping facility that removes load from a larger downstream treatment plant; the current hydraulic load is consistently 9 MGD. Pomona WRP receives high diurnal influent total Kjeldahl nitrogen (TKN) and biological oxygen demand (BOD) load spikes. Solids from Pomona WRP are discharged to a downstream treatment facility for treatment.

Pomona had several drivers for pursuing SBNR operations. “Prior to this project, Pomona WRP was on the cusp of major aeration upgrades. The centrifugal blowers were more than 50 years old and had no ability for significant airflow turndown,” said LACSD Supervising Engineer of Water Reclamation Plants Section, Thomas Weiland, PE. The operational inefficiencies in these blowers meant that the plant was using more than 1,300 kWh/MG influent treated, which is at the top end of the industry average (850 to 1,300 kWh/MG influent) in a state where electricity is at a premium and supply is sometimes undependable. Process air control was minimal, using Proportional Integral Derivative (PID) controllers on two air header valves to achieve the desired DO in the selected aeration zones. Plant operators wanted better and more accurate control in achieving effluent nutrient concentrations.

“As part of this project, the facility was retrofitted to allow for more energy-efficient operation and to facilitate process and aeration for suboxic operations,” said Weiland.

These retrofits included:

“This DOE project is the first application where state-of-the-art high-efficiency blowers and controls were combined with a focused design to reach low DO operations while maintaining or improving nitrogen and phosphorus removal,” said Natalie Beach, PhD, PE, Lead Wastewater Technologist and Low DO Lead at Carollo Engineers.

Based on careful planning with operations, engineering, research and development, laboratory staff, and outside consultants, Pomona WRP’s approach to lowering DO was to first confirm that the controls system would meet a narrow accuracy around DO setpoint and then gradually reduce DOs to suboxic conditions.

“Important steps in getting team buy-in included providing simulations of the new controller performance based on current diurnal cycling, understanding boundary conditions in which the plant was comfortable operating (i.e., minimum aerobic solid retention times (aSRTs), maximum and minimum DOs, etc.), and outlining a systematic reduction of DO setpoints using ABAC controls to reduce the likelihood of plant upsets and ensure regulatory compliance,” Weiland said.

For the low DO transition, ABAC was implemented using ammonia setpoints as the primary controller and DO setpoints as a secondary controller loop. The DO setpoints are maximum aeration setpoints to force the system to lower operational DOs. The adaption was rapid, above 1.1 mg DO/L, requiring between two to seven days (0.3 to 1.2 parts). For DOs below 1.0 mg/L, a minimum of three aSRTs were required between DO changes for consistent system performance and adaptation.

Pomona WRP: Low DO Operations Have Maintained Effluent Quality with Significant Energy Saving

A combination of ABAC controls on ammonia and limiting the DO operating range allowed the Pomona WRP to maintain ammonia discharge limits at levels comparable to before the low DO through the transition (Figure 2).

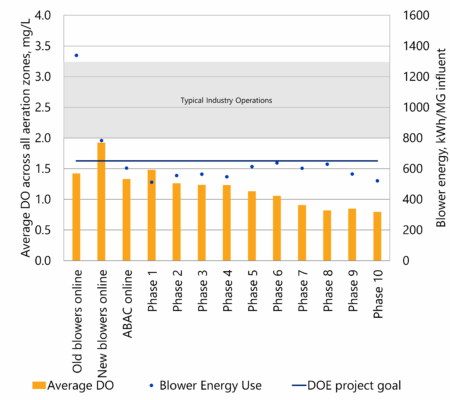

“This excellent performance was achieved at the same aSRTs (6.5 d) and total SRTs (9 d), demonstrating that process capacity was not compromised by low DO operations,” Young said. “At the same time, aeration energy consumption was reduced from 1,300 kWh/MG influent baseline to 550 kWh/MG influent (Figure 3), well below the industry standard. In fact, adding high-efficiency blowers reduced blower energy by over 40 percent. Reducing DO setpoints beyond that has added an additional 30 percent blower energy savings.”

Figure 2. Pomona achieved consistent nitrification while DOs were being consistently lowered from a maximum aeration DO of 3 mg/L in Phase 1 to a maximum aeration DO of 1.0 mg/L in Phase 10.

Figure 2. Pomona achieved consistent nitrification while DOs were being consistently lowered from a maximum aeration DO of 3 mg/L in Phase 1 to a maximum aeration DO of 1.0 mg/L in Phase 10.

The ABAC system allowed the process to respond quickly to changing DO demands due to the sudden daily influx of TKN and ammonia. However, the ABAC controls could not reduce ammonia bleed-through to less than 6 mg/L during the four to six hours of high-influent TKN loading each day. To compensate, the plant implemented an intermittent control structure that allows oxygen in the first aeration zone to increase as high as 1.3 mg DO/L during peak loading to reduce ammonia bleed-through. During the rest of the day, DO concentrations are capped at 1.0 mg DO/L per zone.

“Another interesting finding is that the plant can control effluent ammonia to an accuracy level that will significantly reduce the amount of supplemental ammonia required for tertiary chloramination,” Young said.

Figure 3. Transitioning to newer, more efficient blowers significantly improved energy efficiency by 40 percent, but reducing from a maximum aeration DO of 3 mg/L in Phase 1 to a maximum aeration DO of 1.0 mg/L in Phase 10 further decreased energy usage by 30 percent.

References

Ekster, A. et al. (2019) Model Predictive Control Saves 47% of Energy, Improves Nutrient Removal and Reduces Effluent TSS. Proceedings of the Water Environment Federation. Chicago, IL.

Rachel D. Stewart, et al. (2022). Pilot-scale comparison of biological nutrient removal (BNR) using intermittent and continuous ammonia-based low dissolved oxygen aeration control systems. Water Sci. Technol., 85 (2): 578–590.