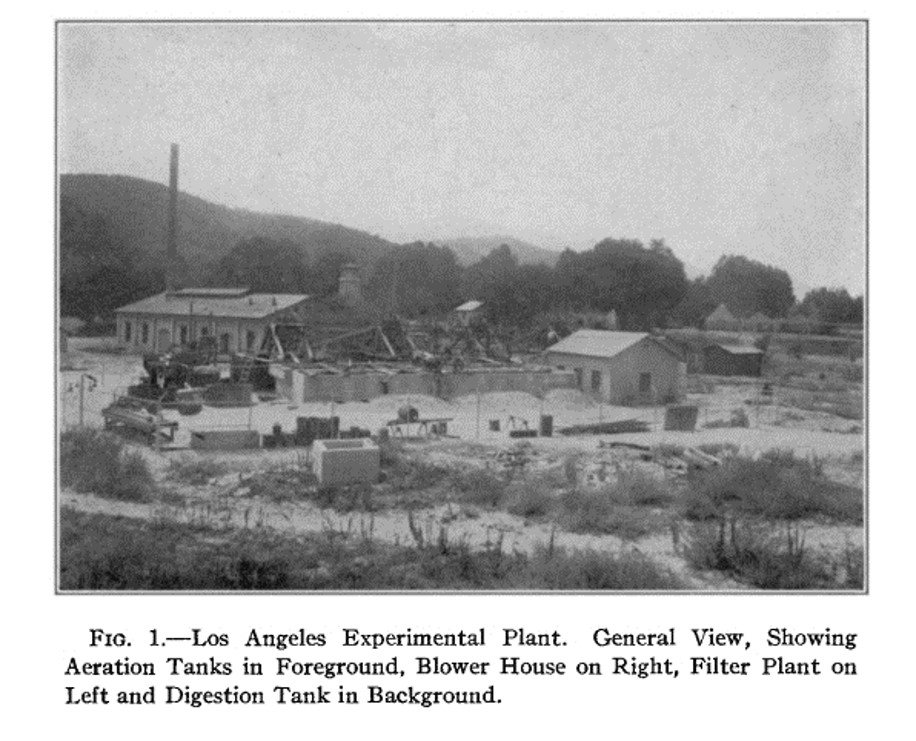

LADWP’s 1930 experimental indirect potable reuse treatment plant near Griffith Park.

In the mid-1920’s, with the Metropolitan Water District of Southern California just forming and the Colorado River water supply not yet secured, the LADWP recognized that its water supplies would be outstripped by the rapid growth and development of Los Angeles. In late 1929, because of the forecast water demands, LADWP officials decided to pursue an ambitious program of sewage reclamation field studies “on an experimental basis” with the stated goal of determining if reclaimed water could be safely used to recharge underground water storage either directly or indirectly through irrigation.

R.F. Goudey, CA Sewage Works Association President

R.F. Goudey, who had recently joined the LADWP as a sanitary engineer, was given the task in January 1930 of designing and constructing the first large-scale complete demonstration reclamation plant on the West Coast. Goudey was the perfect choice for leading the program and project. His professional working career and association work in water and wastewater combined with his presentation style (as evidenced in his technical papers) allowed him to easily bridge the gap between water professionals and wastewater professionals and effectively communicate the benefits of indirect potable reuse.

A location in Griffith Park, adjacent to the Los Angeles River and North Outfall Sewer (serving the San Fernando Valley), was selected for the plant site to allow for groundwater recharge immediately upstream of an LADWP infiltration gallery and pumping station serving the City water system. Goudey, under the direction of LADWP Director of Sanitation Carl Wilson, successfully finished the experimental (pilot) reclamation plant’s design and construction in four months and the plant officially began operation on May 12, 1930.

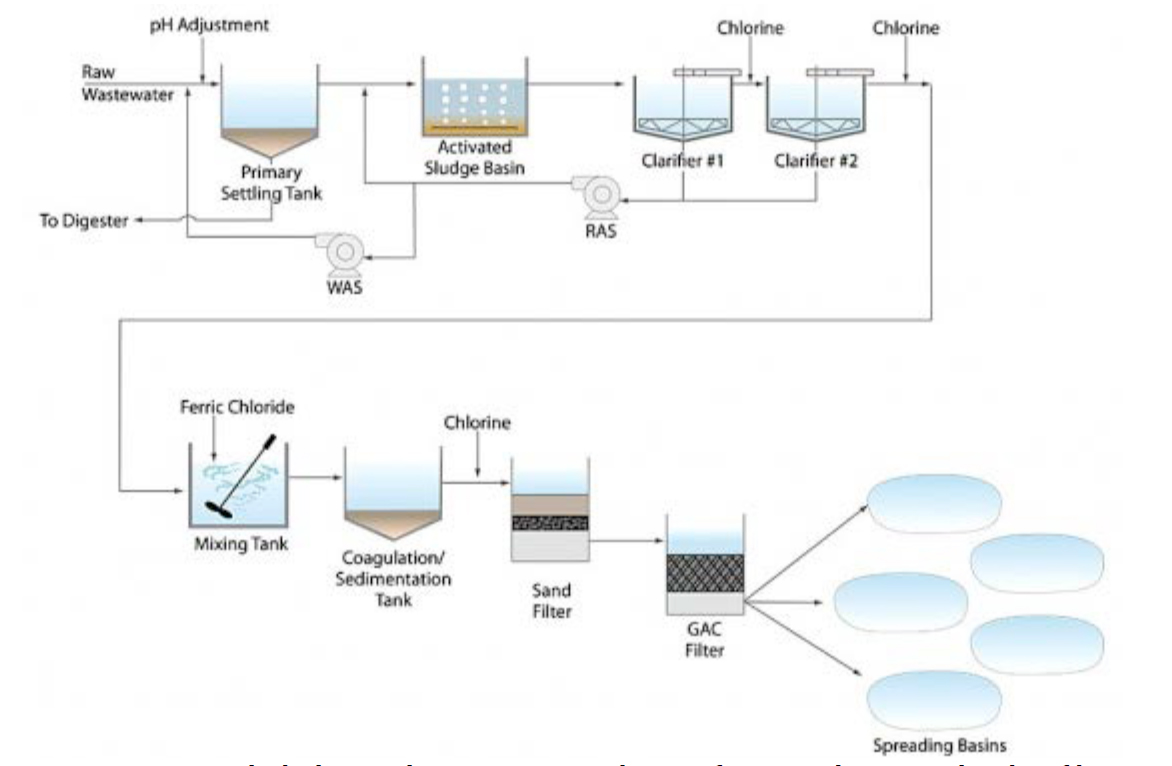

Per Goudey’s papers, the Los Angeles Sewage Reclamation Plant was designed to treat 200,000 gallons per day (0.2 MGD). The activated sludge process was selected for the reclamation plant along with primary sedimentation, anaerobic sludge digestion, and secondary sedimentation/clarification. Gas from the digester was collected and used to run a gas-powered engine generator to provide electrical energy for the sewage reclamation plant.

The secondary effluent was given complete “advanced’ treatment that included chemical addition, coagulation, sedimentation, sand filtration, flocculation, super-chlorination, and finally dechlorination by filtration with activated carbon. The activated carbon also removed trace odors and taste in the water. The final effluent was th en placed on five sand spreading beds to percolate into the groundwater at a measured rate of 1,000,000 gallons per acre per day. Fourteen 2-indl diameter monitoring wells were installed in and around the spreading beds to monitor both groundwater levels and water quality, and to also provide data on the water quality impacts to the down gradient infiltration gallery.

The plant was designed for flexibility to allow for different flow regimes and for process changes so that data could be gathered to meet the objectives of the scope of work and deliverables for the reclamation studies. Every process in the plant was fully metered and measured and composite samples of plant process flows were collected continuously via automatic flow-propertioned samplers.

The site for the Los Angeles Sewage Reclamation Plant in Griffith Park was adjacent to the recently constructed 48′ trunk sewer serving the San Fernando Valley (North Outfall Sewer). The influent to the plant was conveyed by a vertical diversion in the trunk sewer, which allowed the raw sewage to flow into the plant by gravity. The influent flow could be split between two 20′ diameter primary clarifiers equipped with Dorr center drive mechanisms. The primary clarifiers we re also equipped with a chemical feed system to enhance sedimentation and allow for pH adjustment when needed.

The primary effluent was fed to two rectangular aeration tanks equipped with an air diffusion system using “filtros plates. The tanks were continuously mixed with a set of “Imhoff’ paddles that revolved at 6.5 r.p.m. against the diffused air. The aeration tanks were divided into compartments, which allowed tests of various aeration/re-aeration combinations and multi-stage treatment. The multi-stage testing led to some interesting findings, including an effective process of step-feeding of return activated sludge and a process for the thickening of waste activated sludge.

The effluent from the aeration tanks could be settled in one or two circular secondary clarifiers (22′ in diameter and 20′ in diameter) depending on the process flow being tested. It was found that two-stage clarification, where two secondary clarifiers were used in series, worked best for purposes of suspended solids removal and chlorination, with the second clarifier acting somewhat as a chlorine contact basin.

Chlorine was applied to the secondary effluent at a rate of approximately 20 Ibs. per million gallons using Wallace & Tiernan chlorinators. After chlorination, the secondary effluent was treated by adding ferric chloride using a chemical feed system invented by LADWP Director Carl Wilson. The ferric chloride was “flash mixed’ with the effluent and coagulation/sedimentation and took place in a specially designed tank with a one hour detention time. The settled floe was returned to the aeration tanks. Chlorine was also applied at the end of the coagulation/sedimentation tank to oxidize any remaining organics.

The coagulation/ sedimentation tank effluent was applied to a sand and gravel filter (sand depth 12′ and gravel depth 18′) by nozzles that also were used to keep the surface sand agitated. The filter incorporated a backwash system and troughs to convey the filter backwash to the aeration tanks.

The sand filter effluent was applied to an up-flow activated carbon filter constructed to the same dimensions as the sand filter. The carbon filter was vented and had a steam system for regeneration. The activated carbon served to dechlorinate and remove any residual color or odor from the final effluent. This “polished’ effluent could then be applied to the spreading basins for percolation or discharged directly to the Los Angeles River.

Sludge handling for the plant was accomplished with a sludge thickener/decanter and a 20′ diameter, 10′ deep heated anaerobic digester. Waste activated sludge was thickened and mixed with primary sludge prior to feeding it to the digester. Digester gas was collected and used to run an engine-generator, or burnt to waste if it wasn’t needed.

The exhaust heat from the engine-generator was used to heat the digester via a heat exchanger and it was calculated that the Ford engine produced approximately three times the heat needed for the digester. The digested sludge was applied to a sand drying bed and tested as fertilizer for various plants and trees.

Today it’s hard to imagine food processors and canneries in North Hollywood and Burbank, but food processors formed the major industries (along with movie studio film processing waste) that discharged to the City of Los Angeles’s San Fernando Valley Trunk Sewer, or North Outfall Sewer, in 1930.

The Bonner Fruit Company Cannery (peaches, other fruit), the Libby McNeill and Libby Cannery (fruit, pickles, tomatoes, relish), the Genevieve Jackson Inc. fruit/vegetable dehydration plant and the Andrew Jergens Company (soap manufacturing) all contributed to the industrial waste flows that were treated by the Los Angeles Sewage Reclamation Plant. Food processing produced seasonal discharges that varied, depending on the crops being processed, and could produce wastewater two to three times stronger than the average wastewater strengths generated by the rest of the City of Los Angeles system.

The industrial waste from the canneries, soap, and movie industries posed a challenge for the Los Angeles Sewage Reclamation Plant. Not only was the raw sewage “two to three times stronger” than the average strength of the raw sewage at the City’s Hyperion treatment plant, the reclamation plant influent was often septic and the plant operators had to contend with whole peaches and tomatoes showing up in the primary clarifiers during canning season. Additionally the influent pH would drop to 6.4 due to the cannery wastes.

Fortunately, the plant’s design had incorporated features, such as chemical feed systems and conservative design criteria that allowed the operators to adjust pH, flow regimes, and aeration to accommodate the heavy loadings and seasonal fluctuations.

LADWP Experimental Plant image from a 1930 CWEA journal.

Overall, the Los Angeles Sewage Reclamation Plant’s performance was a success and R.F. Goudey’s program was instrumental in gaining support from agencies and the press for indirect potable reuse and recycled water in general. Goudey led many tours of the plant and it is estimated that approximately 500 people visited the facility while it was in operation, and around 300 of the visitors actually tasted the plant’s product by drinking a sample of the final effluent at the end of the tour.

By 1933 the Los Angeles Bureau of Engineering outlined a plan to divert 25 MGD from the North Outfall Sewer in the San Fernando Valley to treat and use for irrigation and groundwater recharge. Despite the success of the plant and the plans to expand the program, the plant was closed and the plans for recycled water were dropped around 1934.

The end of the LADWP project may have been due to the Metropolitan Water Districts securing the Colorado River water supply thus making recycled water appear unnecessary for water supply augmentation.