Read our first article “The SLO Mystery: What Caused a Sudden Drop in Nitrification?”

It’s a nightmare every wastewater operator fears – one day your secondary and nutrient removal processes are humming along and the bugs are happy. The next, the biomass is dying, ammonia levels begin rising, turbidity goes up and the process is heading towards a treatment plant upset.

What slug of chemicals just hit your water resource recovery facility (WRRF) and how do you get thew biomass back up and running?

During the pandemic, deep cleaning became common place and sales of disinfectants with quaternary ammonium compounds (QACs for short) skyrocketed. QACs are a leading suspect for the fall 2020 disruption to the nutrient removal process at the City of San Luis Obispo’s WRRF.

We talked QACs with wastewater treatment experts Dr. Michael Falk and Dr. JB Neethling from HDR Engineering. What is the chemical doing to the treatment process? They also provide basic checklist for operators.

HDR works with several Midwest meat and food processing facilities on their wastewater treatment plants where QACs have been in use for decades. To Michael and JB, the challenges with QACs are nothing new.

Source: Schrank et al. (2020) Are Quaternary Ammonium Compounds, the Workhorse Disinfectants, Effective against Severe Acute Respiratory Syndrome-Coronavirus-2? ACS Publications: Infect. Dis., 6:1553-1557

What are quaternary ammonium compounds or QACs?

Michael Falk, HDR

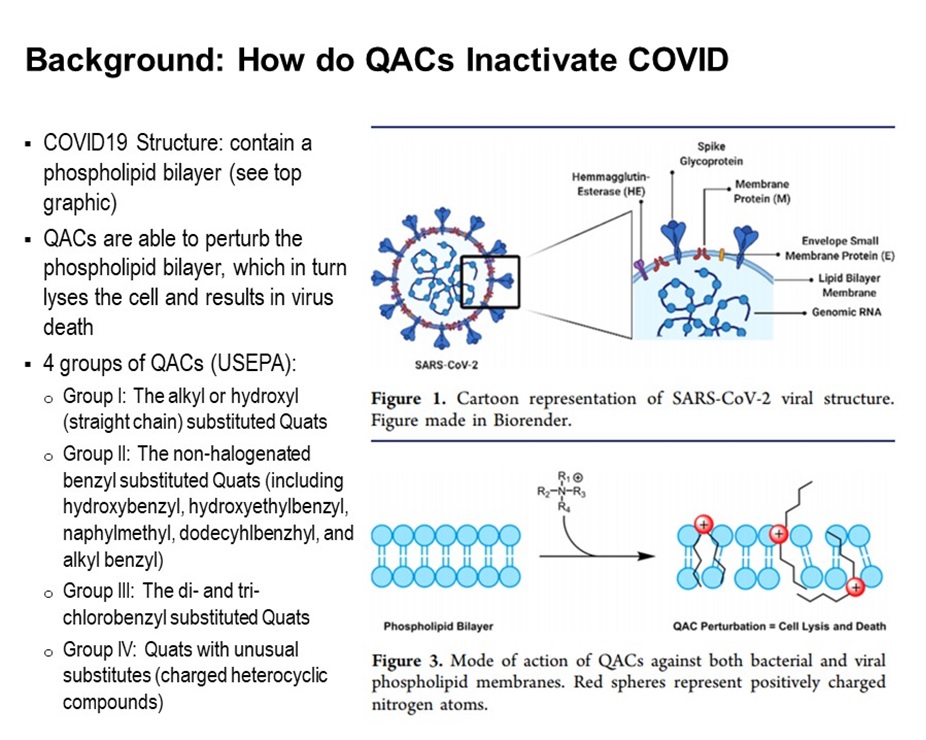

Michael: QACs are a family of compounds, primarily used as antimicrobial ingredients in things such as disinfecting sprays, soaps, wipes, hand sanitizers, and for industrial cleaning applications, such as meat packing, electronic chip manufacturing and the list goes on.

They’ve been around for over 100 years and it’s important to understand how they inactivate viruses and bacteria.

Viruses and organisms have a phospholipid bilayer on the membrane surface, and QACs have a nitrogen atom that essentially penetrates that, with the goal of lysing or breaking up the cell to destroy it.

With COVID-19 and the global pandemic, the use of QACs has increased exponentially, and the end result is more of these compounds are ending up at the local WRRF.

The EPA has a list of approved disinfectants to use during the pandemic and there are over 400 of them. QACs make up 200 of the approved disinfectants, so it’s in widespread use.

How are QACs getting into the sewer system?

Michael: As you think about all the deep cleaning that is going inside rooms and buildings you’re going to rely on a lot of cleaning sprays, rags, wipes, mops and so forth.

A lot of those things end up in the sink to get rinsed. The QACs make their way to WRRFs, it’s estimated that about 75% of the QACs end up at the treatment plants. O

The treatment plants are a really good indicator of the use of QACs within the watershed.

As this became a more pressing issue, a literature review pointed out that by and large, the concentrations WRRFs typically see is on the order of less than one milligram per liter (mg/L).

JB Neethling

JB: The alternative to QACs is to use something like chlorine. The one, big difference between QACs and chlorine is QACs will stay. When it goes into wastewater and it travels to a treatment plant, it’s unchanged and impacts the biology there.

Chlorine, when it goes into the wastewater, there are so many chemical reactions that happen along the way it never reaches the WRRF.

For industrial application, such as the meat packing industry, they have limits in place on the use of the QACs inside the facility. Across the food processing industry during heavy wash down or cleaning procedures those facilities monitor what they add, and sometimes offset cleaning to protect their onsite wastewater treatment facility.

They will alternate by using QACs on Monday, Wednesday, Friday, and using chlorine on Tuesday, Thursday, Saturday. This lowers the overall dose of QACs into their treatment plant.

Michael: Then we get to the question – how much is too much?

It really depends on your treatment objectives are. If your process performs secondary treatment, as most California WRRFs do, your biology is a more resilient.

If you are doing a nutrient removal process such as ammonia removal through nitrification, the nitrifiers that do the ammonia removal are more QAC sensitive group.

What we’ve found is plants performing secondary treatment, you’re safe up to about 10 parts per million or 10 mg/L.

Facilities that nitrify, they will start to see some impacts anywhere from 2-5 mg/L.

And it gets a lot worse as you go up. The bottom line here is plants that perform nitrification are more heavily impacted by QACs.

Which brings me to the San Luis Obispo experience.

Historically, concentrations coming into the WRRF are less than one mg/L.

At San Luis Obispo in September 2020, they saw levels creep above 10 mg/L. So, quite a monumental jump.

It’s unclear exactly what prompted this, the theory is this is around the time students moved into their apartments, where they might not be going to class but a lot of them are living in town. Coupled with some deep cleaning that might have happened on campus. You had this tremendous increase in QAC concentrations.

The plants that nitrify, which the SLO WRRF does, you start to see impacts anywhere from 2-5 mg/L. They were seeing 10 mg/L. The plant was heavily impacted by this slug of loads that came in, and it essentially wiped out the biological treatment process.

The month of September is always challenging for the WRRF as school goes back into session. Their flows into the plant increase 25 to 50%. It happens all at once and the biology needs to catch up to that, which can takes days, even weeks. Couple that with this QACs incident, it just seems to align with school back in session.

What are QACs doing to the WRRF’s biologicals/microbes?

JB: Sometimes we call it inactivate, killing is also an acceptable term. The microorganisms stop reproducing. They stop functioning and the sensitive species are the nitrifiers. You see the impact on nitrification much sooner.

And then the other organisms, because there are thousands of different organisms, each one has different sensitivity and exposure to QACs. If you’re doing secondary treatment, biological oxygen demand removal, those microorganisms would not be impacted as heavily as those that nitrify.

How can plant managers and operators spot the impact of QACs?

Michael: It’s important to understand that the QACs do not build up in the wastewater system over time. Certain compounds have a distinction that they have an affinity to stay in the plant, they build up. Once you get them in a plant, it’s really hard to get them out.

Whereas with QACs, they pass through. While they’ve done their damage, at least if you restart the facility, it’s not as if it’s this lingering, legacy compound. Once they’re through, they’re through.

I think the SLO WRRF experience really gives a lot of insight into the telltale signs to look for.

I think WRRFs performing ammonia removal in the form of nitrification are more heavily impacted.

The first sign to watch for is you’re going to see incomplete nitrification. By that, the process won’t go all the way to nitrate, NO3 minus. It’ll typically stop halfway at nitrite, NO2 minus. You’ll see a buildup of nitrite and that’s easy to monitor as you look at your discharge values.

It has a ripple effect. For plants that use chlorinate to disinfect, you’ll start to see an increase in chlorine demand. It’ll be noticeable, four to five time increase in daily demand. That’s known as a nitrite lock.

You can also see a deterioration in the water quality leaving your biological process out of your clarifiers. In particular, you’ll see an increase in turbidity and total suspended solids.

SLO is really good at keeping a tally of their data. Ammonia concentrations entering the plant are typically between 40 to 60 mg N/L. During September 2020 there was an increase in concentrations, and that’s not entirely surprising. It’s a marginal increase. It’s not something that should translate to an inactivation of the nitrification process.

Whereas when that increase happened, which correlates with the students coming back to school, the green triangles represent the nitrite levels. Which, as you look back to pre-September, there’s rarely any increases, with the exception of a blip back in June. It’s typically less than one or two milligrams per liter. But it goes up to 30 to 40 mg N/L, and even higher. As well as bleed-through of ammonia. So, there is quite a bit of incomplete nitrification happening.

On the next graph, there’s a reflection of what happened to the turbidity and the total suspended solids leaving the secondary process through their clarifiers, where the red line represents turbidity, which typically anywhere from three to 10 nephelometric turbidity unit (NTUs). It spiked up to 15 to 20 NTUs. And then your total suspended solids (TSS), which is typically less than 20, went all the way up to 40 mg/L.

There is this relatively quick response to it, where the nitrite buildup, the ammonia bleed-through, and then just the quality of the water with respect to the solids leaving the biological process deteriorated. Those are some telltale signs, as well as the chlorine demand.

Once QACs are spotted, what can a facility do to stay ahead of this?

Michael: There are some things you can do with respect to monitoring for QACs.

You can buy various test strips. The challenge with those, though, is they’re a bit hard to read. They’re also focused on levels that would reflect industrial applications, in the range of 50 to 100 mg/L.

Hach now offers a low range test kit, which can measure down to 5 mg/L. It’s on the cusp of being helpful as an indicator.

Then there are several titration-based methods you can use. You could either send that to a lab, or your in-house lab. At the end of the day, that’s just another thing for your lab to do, but it can be very helpful.

There are also bioassays that can be done, such as MicrotoxTM.

Finally, if the WRRF is required to do whole effluent toxicity testing, you can incorporate looking for QACs into your effort as well.

JB: It’s an impact on the biology, and you’ll see the nitrification go out first, and the nitrite build-up.

The thing about this, it’s often short duration, so it comes and it goes. It’s like the prior graph showed. You saw a rise in the effluent, and then it came down again. Even if you stop the addition of QAC, the bugs are killed. It takes a long time for them to catch up again. The recovery can take a while.

How do you find these things that only happen occasionally, without warning, and then it goes away? By the time you marshal up the forces to sample and measure, it’s long gone. It’s very hard to do.

Is the challenge the same across for all WRRFs – large, medium or small?

JB: Well, the big WRRFs get the advantage of dilution. So the smaller plants are often much more impacted because it’s a smaller biological community, and if you have one industry in town, it can dominate the load.

I worked at a plant in the Central Valley, where there was one industry that would basically increase the BOD by 10 times over a weekend. Then it stays up because cannery in town started operations. All the fruit came in. It was ready to go.

The town was small, and it’s a big industry. So the industry has huge a impact. But you go to Hyperion serving 5 million people that is a huge service area. The wastewater averages out over time, so you don’t have the same impacts.

We also see these impacts at ski resorts. Weekend loads, the start of the ski season.

I saw it once at USGA golf tournament in Pebble Beach. They had trouble meeting the Title 22 treatment requirements for recycled water used to irrigate the golf course. We thought the reason could be the porta potties. There were so many for all the people that showed up for the weekend, and that impacted the wastewater treatment plant. Turbidity went up, and they couldn’t meet Title 22.

People love cleaning, how does the wastewater community respond to QACs?

MIKE: The underlying challenge here is the EPA’s list of recommended disinfection compounds for COVID-19, QACs represent nearly 50%.

I think getting the Hach test kit is a worthwhile endeavor for plants to have on hand. Understanding industries and events in your sewershed that may potentially impact treatment when they start-up.

We talked about Cal Poly San Luis Obispo and the return to school.

There are also rentals and hotels in resort areas that will do a deep cleaning. I can imagine on a Sunday, there’s going to be some deep cleaning that goes one. When the flow makes its way to the WRRF, how is it going to respond to that?

In terms of strategies to address this, unfortunately, the solutions are not great. It’s not just flick a switch and you address it.

One recommendation we talked to SLO about was to reduce the amount of biology that you wasted. Typically, you’re continually wasting a little bit of the biology to keep the process in a steady state (known as waste activated sludge or WAS).

Rather than waste that, let’s keep it in the system as a buffer, since you’re trying to build back the biology. Once you lose that biology to a kill, it’s going to take weeks to recover. You’re going to need to bring in a seed. And even with a seed, it still takes days, if not weeks, to get you back.

In terms of treatment, there are some compounds that can help.

There are non-surfactant chemistries that bind up the QACs. An example here is NeutraQuat. But as you can imagine, these are specialized organics you’re adding. They’re quite expensive and if you’re up against wiping out your biology, it’s, in my mind, money well spent.

However, as JB mentioned earlier, it’s not possible to constantly monitor for these things. As soon as the QACs come in, you need to be proactively addressing it. How do you get the timing down where you see the QACs and are adding the non-surfactant chemistry?

Is it a good idea to search for the source of the QACs?

Michael: We have to ask are they searching for a needle in a haystack? I think WRRFs in California can look at an inventory of their heavy users.

As JB mentioned earlier, HDR has done work in the Midwest with the meat packing industry. Having those conversations with industrial users is important.

Do they use these QACs? If so, what is it a daily occurrence?

Can they meter it over time so the impact on the plant is not a one-off event? Can they change up their disinfectants and use chlorine or an ethanol-based disinfectants on a rotating schedule.

It’s trying to figure out a means to attenuate those slug loads of QACs. That’s really what it’s about.

JB: Tracing the source is difficult since it’s often an interim thing. It happens, and then it quickly goes away.

I recall one incident where we had a small plant lose nitrification. When they researched it, they found out the sewer crew was doing pipeline cleaning next to the WRRF and adding root mitigation chemicals and dosed a little bit too much. But was that the exact cause? We don’t know. We don’t have any samples. The root agent came in and nitrification decreased. What we know is the city oversees both the treatment plant and sewer workers and they could make the connection.

The clues might not always be that obvious.

In the end, you piece things together and say well, it points in this direction. But full proof may never be achievable.

So QACs impacted SLO, how many other California WRRFs are impacted?

Michael: It really comes back to these compounds have major market penetration. Again, they represent half of EPA-approved disinfectants. So, they’re widespread.

I would say that while San Luis Obispo is an exceptional case study, it was somewhat in my mind a perfect storm.

The QACs will typically be diluted out. The cautionary tale is really for plants that perform biological ammonia removal as they are the most sensitive WRRFs

I think public education and outreach are something that should be considered. I look back at the success of preventing mercury fillings from going down the drain thanks to the Dental Association’s coordination and how successful that’s been.

Let’s talk about the importance of alcohol-based and chlorine-based cleaning products instead of QAC based compounds. There’s no silver bullet.

We’re coming to the end of the pandemic (thank goodness) so will the challenges with QACs just go away for the wastewater community?

Michael: For university towns, resort areas, towns with large industries, we don’t think the use of cleaning products is going to go away. I think this is something that’s ingrained in our society now.

In recent news and scientific studies, surface inactivation and disinfection don’t really seem to be the solution to preventing COVID. Nonetheless, it’s part of our society now, so I don’t anticipate this going away.

To give you a feel for how much the use of disinfectants have increased, one of the manufacturers of over-the-counter disinfectants noted that during the month of May 2020, their production demand reflected the entire year of 2019. Just one month, represented the entire year of 2019.

It seems like the demands for these cleaning products are going to continue into the future.

JB: I don’t see it going away. We don’t know the extent of the impact, the magnitude on treatment plants. If it’s going to be a low-level thing, then it’s not going to be noted. But if it’s suddenly a heavy dose, then you’ll see the impact on the treatment process.

What other recommendations do you have for operators?

Michael: I think there is a checklist operators should have.

The tell-tale signs. The nitrifiers specifically are sensitive, and they can really serve as your “canary in the cave.” What you will see is ammonia bleed-through, nitrite, 2-minus, buildup. Which will have a ripple effect that you’re going to see an increase in chlorine demand, known as nitrite lock. Operators should be familiar with those scenarios.

In addition, the quality of the water in the form of turbidity and total suspended solids is going to deteriorate.

It seems like the Hach test kit is probably your best bet for facilities similar to SLO. It might be worth doing a daily check, just to see if there are any spikes in the QACs.

While there are non-surfactant based chemistry out there to neutralize QACs, that’s something that’s tough to do retroactively.

If your WRRF is negatively impacted by QACs, reseeding is a good way to accelerate biological activity, but it’s going to take at least two weeks to regrow nitrifiers and about two months to reach a steady-state.

Thinking of the bigger picture, other chemicals might upset nitrification and we don’t want to misdiagnose those as QACs. Plants that do nitrification always want to be tracking alkalinity, because if you’re short there, it’s going to result in incomplete nitrification, or a shutdown of it.

As JB mentioned earlier, root cleaning and chemical applications within a sewer system is something we’ve found can have very similar implication as QACs and will impact nitrification. Be mindful of that coordination.

JB: Any town, the smaller the WRRF, the more vulnerable you are, and the more exposed you are to industrial and seasonal activities. If you have a hotel preparing for ski season you may get a slug of cleaning compounds all at once. Those are the things to watch for.

Should society put down the harsh chemicals to save wastewater bugs and we encourage people to use green chemistry?

Michael: Interesting question. Trying to get an industry to use greener alternatives might result in some initial pushback because they’re reluctant to change things if they know it works.

I do see a lot of value in advancing green chemistry. On paper at least, the idea seems grand, and something to strive towards.

JB: There’s always the balance between risk and reward. And you want to be safe. We want meat that’s safe to eat. We don’t want meat to get contaminated, so you want to do a good job disinfecting food processing facilities to meet the highest standards.

You want to disinfect counter spaces and the environment where food is being prepared. The way you do that most effectively today, is by using one of the approved disinfecting chemicals.

QACs turn out to be a very helpful chemical because they’re very effective. I am all in favor of finding something green that is equally effective and equivalent in cost. It’s a balance we must find.

—————————

Graphs and tables prepared by HDR.

Michael Falk is a Senior Professional Associate at HDR where he specializes in process engineering at water resource recovery facilities with an emphasis on nutrient management. He has been employed at HDR since receiving his PhD from UC Davis in 2008. This work is based on the EchoWater Project at Regional San (Sacramento, CA) from planning through start-up and commissioning plans.

JB Neethling is HDR’s top wastewater process engineer, with day-to-day tasks ranging from master planning, process evaluation, and modeling, to design and startup of wastewater treatment plants. As technical director for wastewater treatment and effluent management, he assesses new technologies and directs technology transfer and applied research activities within HDR.

He is passionate about national and local biological nutrient removal issues, including serving as the principal investigator for Water Environment & Reuse Foundation’s Nutrient Removal Challenge Program and nutrient strategy assistance for Bay Area Clean Water Agencies. His accomplishments include oversight of all BNR-related research conducted through WE&RF, including ongoing efforts to achieve the lowest effluent total phosphorus requirements in the nation. He consults with clients nationwide regarding regulatory issues and related designs.