By Paula Hansen and Artem Dyachenko

East Bay Municipal Utility District

Ultraviolet germicidal irradiation (UVGI) is a disinfection method that uses short-wavelength ultraviolet (UVC – approximately 254 nm) light to kill or inactivate microorganisms (e.g. bacteria, viruses, molds, and other pathogens). It destroys nucleic acids of the microorganisms and disrupts their DNA, leaving them unable to perform vital cellular functions.

UVGI is used in a variety of applications, such as food, air, and water purification, hospital rooms disinfection, and, increasingly, in public spaces of public transportation and schools. UVGI is a very efficient and environmentally-friendly method (no chemicals involved) and it can be used in conjunction with other manual cleaning methods.

Due to these benefits, the US Environmental Protection Agency (EPA) is actively evaluating the use of UV light as one of the technologies for large-scale disinfecting needs at schools and offices.

During the State-wide Shelter-In-Place Order period, the East Bay Municipal Utility (EBMUD) has continued its essential work of providing safe drinking water and treating wastewater for its 1.4 million customers east of the San Francisco Bay. To ensure its employees can work safely to protect public health and the environment during this global health crisis, the EBMUD Laboratory has evaluated the UVGI for two distinct applications:

EBMUD’s Laboratory routinely performs analysis of samples for monitoring drinking water, wastewater, recycled water, biosolids, and trucked-in wastes for regulatory compliance, process monitoring, and special studies. The Laboratory has continued to provide these critical services and remained fully operational during the COVID-19 pandemic. Concerns arose on exposure potential in a highly-used Laboratory room for sample drop off and supplies pick up. This room is frequently used by many people from various groups, including Laboratory staff, water and wastewater operations, and outside clients.

To enhance sanitation measures and minimize potential health risks of staff in performing uninterrupted essential services, EBMUD has evaluated and procured mobile UV equipment to be used in conjunction with manual cleaning processes inside their analytical laboratory facilities. (If you would like details about the manufacturer, please reach out to the authors. Their contact info is below.)

Evaluation Criteria Used

Summary of UV Equipment Suppliers Evaluated

Information on equipment design, cost, and availability was obtained from a variety of suppliers. UV equipment designed for use in healthcare settings such as hospitals and nursing homes incorporates features primarily of interest to those users such as in-person training and cloud-based data tracking and storage. These medical grade units are robust but are significantly more expensive; less flexible with additional support and warranty features; and have longer delivery times (currently in the ballpark of 10–18 weeks). Approximate costs for equipment designed for the healthcare market is in the range of $45,000 to $125,000. The approximate cost range for equipment designed primarily for industrial applications is in the range of $5,000 to $30,000.

The disinfection time to treat a 12 ft x 12 ft room ranged from less than 30 minutes to more than 60 minutes. The power output varied from 600 watts to 1800 watts. Some suppliers also offer the leasing option.

Safety Measures

To use the selected UV equipment, safety measures specific to UVGI will be implemented. Mobile UV equipment is meant to be used in unoccupied rooms. To minimize risks of harmful UVC exposure, eyes and skin must be protected at all times while the equipment is in use. Additional measures include placing 100% UV-protective removable (adhesive) film on room windows and posting warning signs on doors leading to rooms with UV disinfection in progress. Trained operators must use Personal Protective Equipment (PPE) including UV protective goggles and face shield, lab coat, and gloves. A UVC radiometer should be used to periodically confirm lamp intensity necessary to achieve the target dose (>0.5 J/cm2) and to verify performance of UV blocking window films.

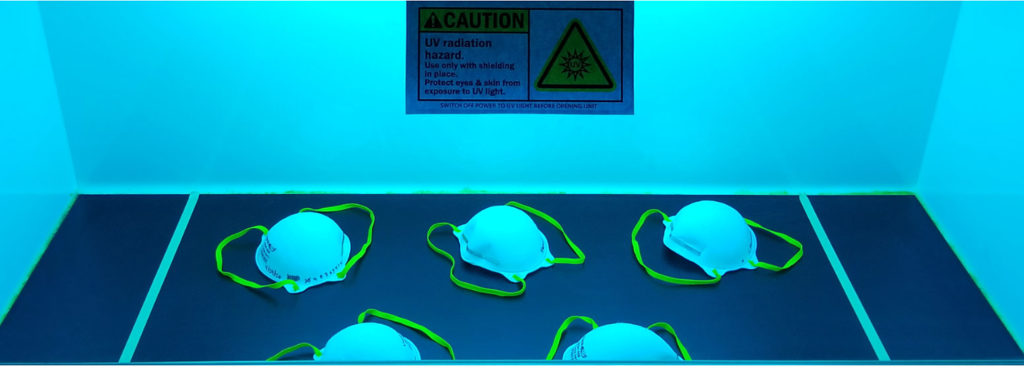

Many water and wastewater workers need to use N95 masks to perform their essential work due to exposure to particulates or aerosolized wastewater. UVGI can also be used to disinfect lightly used N95 masks to allow re-use. The method was originally developed by the University of Nebraska Medical Center and is recognized by Centers for Disease Control and Prevention (CDC) as an effective approach to dealing with the shortage of PPE. It is only suitable for certain types of N95 filtering facepiece respirators (FFRs) that have no valve, feature smooth surface and are able to maintain their shape to ensure uniform UV light dose is delivered to all mask surfaces. A recent study conducted by the National Institute of Health (NIH), highlighted UVC effectiveness to inactivate the novel SARS-CoV-2 on N95 respirators (R. Fischer, et al. Assessment of N95 respirator decontamination and re-use for SARS-CoV-2).

When the masks were in severe shortage in the early days of the COVID-19 pandemic, to conserve the precious respirators, EBMUD Laboratory staff validated a temporary disinfection procedure for N95 FFRs using a high intensity UVGI technique to allow re-use. Please note that the UVGI can only be used to deactivate pathogens, not to remove particulates.

UV cabinet used at the EBMUD Laboratory for UVGI N95 respirators disinfection.

Using CDC shared information on UVC dose for N95 respirators disinfection, the EBMUD Laboratory staff prepared a standard operating procedure which includes: labeling N95 respirators with employee’s name and date of first use, and requiring disinfection after every work shift, not exceeding 10 work shifts or until respirator fit is impacted. The disinfection procedure is performed daily utilizing sterile technique by trained personnel wearing UV protective eyewear and faceshield, nitrile gloves (freshly sanitized for each mask), an N95 FFR, and a lab coat. The disinfection steps include:

Thank you to Paula, Artem and Yun Shang, a Senior Civil Engineer at EBMUD, for sharing this article with CWEA members and helping us get it ready for publication.

Please be sure to check with face mask and UV light manufacturers to ensure you are following proper protocols for disinfection and worker safety protection.