Nitrogen, a nutrient present in wastewater, can have detrimental impacts when discharged into receiving water bodies. East Bay Municipal Utility District (EBMUD) has explored both sidestream and mainstream nutrient removal approaches through its recently completed Master Plan. The agency is also working on a parallel effort to characterize the ability to remove total inorganic nitrogen (TIN) using the existing high-purity oxygen-activated sludge (HPOAS) system. Utilizing HPOAS for nitrogen removal poses several challenges, and available literature at full scale is sparse.

EBMUD provides wastewater treatment services to 740,000 residents in California’s east San Francisco Bay Area. The District’s Main Wastewater Treatment Plant (MWWTP) treats approximately 60 million gallons per day (MGD) of wastewater during the dry weather months—April to October—and has used HPOAS for secondary treatment since the 1970s.

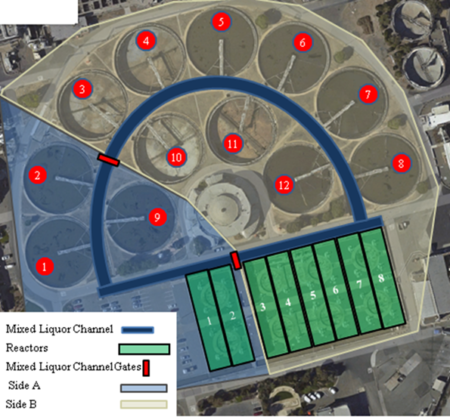

The system consists of eight reactor trains (with four stages each) and twelve secondary clarifiers (Figure A), with a rated capacity of 168 MGD during wet weather. High-purity oxygen is generated from an on-site cryogenic oxygen air separation plant (Figure B).

Figure A: East Bay Municipal Utility District Main Wastewater Treatment Plant layout and split-plant configuration. Side A and Side B operate at high and low mean cell residence times, respectively, during split-plant testing.

Figure B: Cryogenic oxygen generation plant for high-purity oxygen activated sludge process.

In the early 2000s, the first stage of each reactor was converted to an anaerobic selector to control sludge bulking. The EBMUD’s MWWTP has been in perfect compliance with effluent limits in its National Pollutant Discharge Elimination System (NPDES) discharge permit for the last twenty-two consecutive years.

In 2014, the San Francisco Bay Regional Water Quality Control Board issued its first regional order (referred to as the San Francisco Bay Nutrients Watershed Permit) to address the potential impacts of nutrient discharges on the San Francisco Bay. The second Nutrients Watershed Permit issued in 2019 included estimated TIN load targets for each wastewater agency. EBMUD is planning to meet TIN effluent discharge limitations required by the third Nutrient Watershed Permit to be issued in 2024.

“While the MWWTP typically operates at a mean cell residence time (MCRT) of 1-1.5 days, much longer MCRTs are needed to support nitrifying bacteria—the main microorganisms that oxidize inorganic nitrogen,” said Donald Gray, EBMUD’s Manager of Wastewater Technical and Emerging Issues. “The subsequent increase in solids inventory can present challenges to the existing infrastructure, including a much higher solids load to the clarifiers.”

There are additional concerns with insufficient alkalinity for complete nitrification—oxidation of ammonia to nitrite, and then to nitrate, the lack of internal recycle for denitrification—reduction of nitrate and nitrite to nitrogen gas, the potential for rising sludge blankets in the clarifiers from the gas formed from denitrification or nitrite impacts on hypochlorite disinfection.

“EBMUD has performed full-scale TIN removal testing during dry weather for the past three years using its existing HPOAS process,” Justin Shih, senior civil engineer for EBMUD said.

Through a series of valves, gates, and pumps, the existing HPOAS reactor and clarifier configuration can be physically split into two parallel processes with entirely separate biomass (Figure A). This allows for full-scale testing of higher MCRTs to treat up to 25% of the secondary influent flow (Side A) while maintaining the existing process for regular treatment (Side B).

“There is also the ability to configure a 50/50 split. Both sides’ effluent combines before disinfection, dechlorination, and discharge,” he said. “The ‘split-plant’ testing can run for approximately four to six months during dry weather and depending on plant conditions.”

Each split-plant season has provided additional evidence towards both the benefits and challenges of operating an HPOAS system for nitrogen removal. In 2021, up to 74% TIN removal was demonstrated for flows up to 5 MGD (Figure C).

Figure C: Total inorganic nitrogen (TIN) removal in full-scale high-purity oxygen activated sludge process.

On average, the nitrite concentrations in the secondary effluent were more than six times higher than those of nitrate, suggesting a nitritation/denitritation process.

“This year’s focus is to increase effluent flows, evaluate the potential benefits of flocculant use to control effluent total suspended solids, and further explore different operating parameters,” EBMUD assistant engineer, Rogelio Zuniga-Montanez said. “Data collection efforts were expanded from last year by increasing the sampling frequency and analytical tests conducted.”

A nitrous oxide sensor was installed in the high MCRT reactor to evaluate dissolved concentrations of this nitrogen removal side-product and potent greenhouse gas as the process activity evolves, accompanied by planned gas sampling events of the reactor headspace. Mixed liquor samples are regularly sent for DNA sequencing to characterize the biomass to identify the key organisms involved in the process.

“This testing effort has resulted in extensive documentation of the startup and operation of HPOAS at high MCRTs,” Gray said. “Although increasingly less common, many wastewater agencies still successfully operate and maintain their HPOAS systems.”

Gray said that these agencies (including EBMUD) are faced with the difficult determination of whether the system can continue to be rehabilitated and adapted to regulatory changes. Running split-plant testing is an extensive effort throughout the Wastewater Department for Operations, Maintenance, Engineering, and the Laboratory; however, nitrogen removal in HPOAS plants remains a promising strategy for reducing TIN discharges to the San Francisco Bay and elsewhere.

“We look forward to documenting our findings for future publication,” Zuniga-Montanez said.